I-Carbide Cold Heading Die ifa ngendlela ebandayo

- Ukusebenza okuthuthukisiwe: Ngokumelana okuhle kakhulu kokugqokwa, i-tungsten carbide ebandayo iyafa inesikhathi eside sokuphila, inciphisa isikhathi sokuphumula futhi ikhulise ukusebenza kahle kokukhiqiza.

- Ukonga izindleko: Isihloko esibandayo se-Tungsten carbide siyafa singakhiqiza izikulufu eziningi ezinekhwalithi engaguquki, ukunciphisa udoti olahliwe kanye nokwehlisa izindleko zokukhiqiza.

- I-Versatility: Isihloko esibandayo se-Tungsten carbide siyafa singenziwa ngokwezifiso ukuze sikhiqize izikulufu ezinobukhulu obuhlukahlukene, ubujamo, kanye nemiklamo yentambo, izenze zifanelekele uhla olubanzi lwezinhlelo zokusebenza.

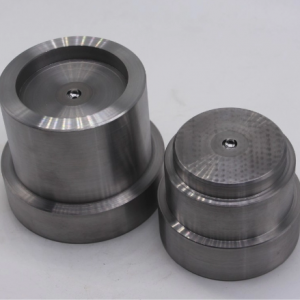

IIsihloko Esibandayo Sifa, futhi ebizwaukufa okubandayo okwakha, iwukufa okukhethekile okusetshenziselwa inqubo yesihloko esibandayo, lapho okungenalutho kwensimbi kwakhiwa khona kube ingxenye ngaphandle kokushisisa.Yakhelwe ukwenza inhloko yebhawodi, isikulufu noma ezinye izibophelelo.Ifa eliyinhloko liyingxenye eyinhloko yesihloko esibandayo sokufa, futhi lisebenza kanye ne-punch nezinye izakhi ukukhiqiza isimo esifiswayo sengxenye.

Izinhlobo ezihlukahlukene zemishini yokushisa ebandayo ziyatholakala, kodwa ukukhiqizwa kwe-fastener, kuvamile ukuthola imishini ene-die two blow eyodwa, kuze kube yisihlanu kufa okuyisithupha, nokunye okwengeziwe.Ukusetshenziswa kwezihloko ze-multi-die kuvumela ukukhiqizwa kwezingxenye eziyinkimbinkimbi ngenqubo eyodwa, okunqoba imikhawulo ebangelwa ukuncishiswa kwesilinganiso sobubanzi.

i-Cold Heading Die iyithuluzi elibalulekile lokukhiqiza izinsimbi ezisezingeni eliphezulu.Ngezinto zayo ezisezingeni eliphezulu, ukunemba kwemishini, kanye nezici ezenziwe ngokwezifiso, ingahlangabezana nezidingo ezidingekayo zezimboni nezinhlelo zokusebenza ezahlukahlukene.

I-RenQiu HengRui iTungsten Carbide ingenza ngokwesicelo sakho, uma isicelo esinemininingwane nomdwebo sesinikeziwe.Ukumelana nokugqoka okuphezulu nokusebenza okuqinile kungafinyelelwa ngokuxhumana okwanele.

Ukufaniswa Kwempahla→Ukugaywa Kwebhola Elimanzi→I-WC exubile kanye Amandla e-Cobalt→Ukucindezela→Izifudumezi Zokuhlanganisa E-HIP→Ukutholwa kwe-QC→Ukupakisha

Sizoletha impahla ekhiqizwe ngobuningi zingakapheli izinsuku ezingama-30 ngemuva kokukhokha kancane, kanti, uma kunezicelo ze-soecific ngesikhathi sokulethwa.Singenza ushintsho ngokwesicelo samakhasimende, ngakho-ke isikhathi esifushane sokulethwa sitholakala ngokuphelele.

Ngokuvamile 30% T/T kusengaphambili, bhalansi 70% ngokumelene B/L ikhophi.Futhi ingashintsha ngokwesicelo samakhasimende.

Senza izingxenye ezinomumo nosayizi abahlukene ukuze zifane nezidingo zamakhasimende ethu ncamashi, kungakhathaliseki ukuthi adinga amabhulokhi noma amashidi, amasilinda, amabheringi, amathiphu noma amazinyo.