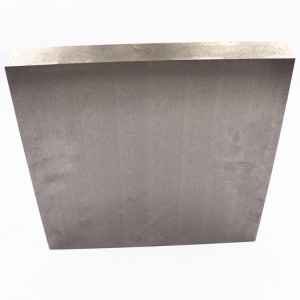

I-100% I-Virgin Material ye-Hip Tungsten Carbide Blocks Izingxenye ze-Carbide ze-Tungsten Carbide Plate

Ukunemba kokugaya ipuleti le-carbide lepuleti le-tungsten lensimbi esethulweni yomkhiqizo

1. Ukuhlanzeka kwezinto zokusetshenziswa kufinyelela ngaphezu kwe-99.95%, okuqukethwe kokungcola kuphansi, futhi izakhiwo ezibonakalayo zebhodi zizinzile;

2. Ukusebenzisa ubuchwepheshe bokumisa isifutho, izinto zivikelwe i-ammonia ephezulu-ehlanzekile ngaphansi kwezimo ezivaliwe ngokugcwele, okunciphisa ngokuphumelelayo amathuba okuba ne-oxygenation ngesikhathi sokulungiselela ingxube.Ubumsulwa bungcono futhi impahla akulula ukuba ingcolile;

3. Ukuminyana kwebhodi kuwumfaniswano: icindezelwa ngomshini wokunyathelisa we-300Mpa isostatic, oqeda ngokuphumelelayo ukuvela kwamaphutha okucindezela, futhi ukuminyana kwebhodi elingenalutho lifana kakhulu: 4. Ukuminyana kwebhodi kuhle kakhulu, futhi izinkomba zamandla nobulukhuni zihlangabezana nezindinganiso: ubuchwepheshe obuphansi be-sintering busetshenziselwa ukwenza ibhodi Izimbobo zangaphakathi ziqedwa ngokuphumelelayo, futhi ikhwalithi

ezinzile.

Isakhiwo sangaphakathi se-metallographic sepuleti singathuthukiswa futhi ukucindezeleka kwangaphakathi kungancishiswa kakhulu, ukugwema ngokuphumelelayo amathuba okuqhekeka kwepuleti ngesikhathi sokusika nokwenza inqubo.5. Sebenzisa ubuchwepheshe bokwelashwa kwe-cryogenic;

[Ibanga lohlelo lokusebenza le-carbide plate ne-tungsten steel plate]:

Ifanele ukwenza ama-cast iron rolling kanye ne-high-nickel-chromium roll yokugqoka kanye nemibese yokubumba;

Ilungele ukwenza amapuleti okukhipha impahla, ukugxiviza kuyafa, i-punch dies, i-electronic progressive dies nokunye ukufa kwesitembu, njll.

Ukwenza ngokwezifiso okungajwayelekile, ukwenza ngokwezifiso okukhethekile.Izithombe nezingcaphuno eziku-inthanethi zenzelwe inkomba kuphela.Izintengo zingahluka kuye ngokucaciswa okuthile, izinto zokusetshenziswa, izindleko, nenani le-oda.

Amabanga Ahlukahlukene Wokukhetha:

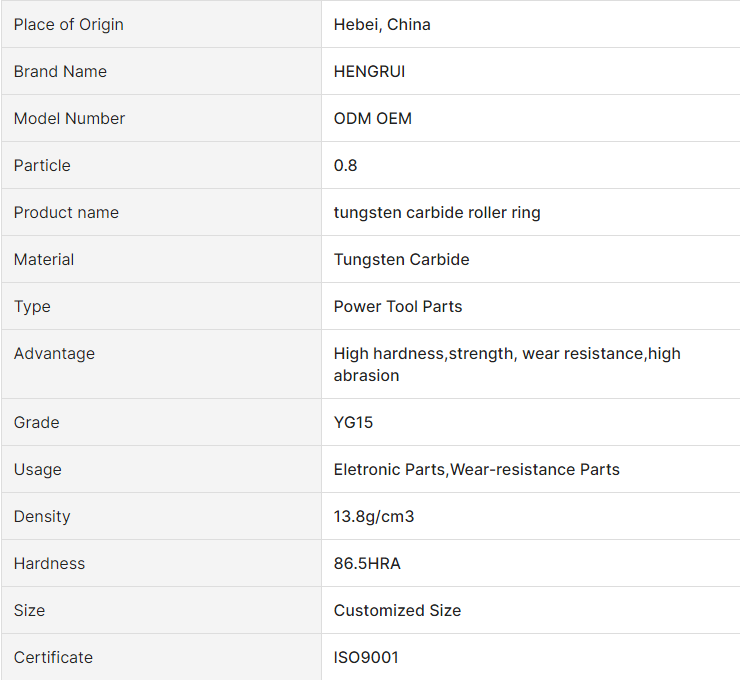

| I-Tungsten Carbide Cold Forging/heading Iyafa | |||||

| Amabanga | Ukuminyana | TRS | Ukuqina | Ukusebenza nohlelo lokusebenza kuyanconywa | |

| g/cm³ | I-MPa | HRA | |||

| YG11 | 14.4 | ≥3000 | 88.5 | Ukwakha noma ukugxiviza kufa ngenxa yezimpushana zensimbi nezimpushana ezingezona ezensimbi. | |

| YG15 | 14 | ≥3400 | 87.5 | Ngokwenza umdwebo ufa ngamashubhu ensimbi nezinduku ngaphansi kwe-High compressibility ratio;ukubhoboza, ukunyathela, ukukha amathuluzi ngaphansi kwengcindezi enkulu. | |

| YG20 | 13.5 | ≥3800 | 85.5 | Ukuze kwenziwe isitembu sezingxenye zewashi, amapuleti e-spring wezinsimbi zomculo, izimbiza zebhethri, amabhola ensimbi anosayizi omncane, izikulufu, ama-screw cap. | |

| YG15C | 14 | ≥4000 | 86.5 | Ukuze uthole izingcezu zokubhoboza ama-cone kawoyela, sika amatshe athambile naqinile aphakathi nendawo; ukubhodla nokusika ukhuni oluqandisiwe, ukhuni oluthambile nokhuni lwangempela. | |

| YG16C | 13.9 | ≥3500 | 85.5 | Ukuqiniswa komthelela kuyafa. | |

| YG18C | 13.7 | ≥3600 | 84.5 | I-Impact resistance forging ifa, i-hot-press forging iyafa namarola. | |

| YG20C | 13.5 | ≥3800 | 83.5 | Ifa ngenxa yokusetshenziswa kokumelana nokugqokwa noma ukumelana nomthelela. | |

| YG22C | 13.3 | ≥4000 | 83 | Ukwakhiwa kwamantongomane kuyafa futhi ukukhanga komthelela omkhulu wokumelana kuyafa. | |

| YG25C | 13.1 | ≥4250 | 82.5 | Ikhanda lebhawodi elingenasici liyafa namarola. | |

Ukufaniswa Kwempahla→Ukugaywa Kwebhola Elimanzi→I-WC exubile kanye Amandla e-Cobalt→Ukucindezela→Izifudumezi Zokuhlanganisa E-HIP→Ukutholwa kwe-QC→Ukupakisha

Yonke imikhiqizo kufanele ihlolwe ngokuqinile nge-ultrasonic futhi yilezo kuphela ezingenabungozi njenge-aspore ingathunyelwa ngaphandle.I-Highdensity, ukugqoka okuphezulu&ukungathinteki, okubaholela impilo ende.

Sineqembu elinamandla nelifundile elihlanganisa: Ithimba labaphathi abantu abayi-10,Ithimba locwaningo abantu aba-5, abasebenzi abangama-77 abanolwazi.10 Abaphathi bokuthengisa.

Samukela ukuphathwa kwesistimu ye-7S-Seiri, Seiton,Seiso, Seiketsu,Shitsuke, Safety,Speed,Saving.Lonke uchungechunge lwemikhiqizo luphethe unjiniyela oyedwa wokuthengisa

Ngokuvamile 30% T/T kusengaphambili, bhalansi 70% ngokumelene B/L ikhophi.Futhi ingashintsha ngokwesicelo samakhasimende.

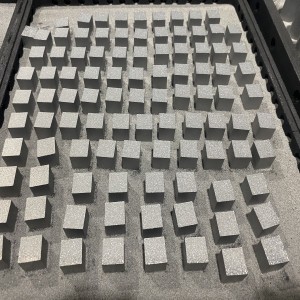

Senza izingxenye ezinomumo nosayizi abahlukene ukuze zifane nezidingo zamakhasimende ethu ncamashi, kungakhathaliseki ukuthi adinga amabhulokhi noma amashidi, amasilinda, amabheringi, amathiphu noma amazinyo.