I-tungsten carbide(WC) iyinhlanganisela eyakhiwe i-refractory metal tungsten kanye ne-non-metallic carbon, enezici zokuminyana okuphezulu, indawo ephakeme yokuncibilika, amandla aphezulu, ukuqina okuphezulu, ukumelana nokushisa okuphezulu, ukumelana nokugqwala, ukumelana nokugqoka kanye nokuhamba kahle kukagesi nokushisayo. , ngakho-ke iyithuluzi elifanele le-carbide.

Kodwa-ke, ngenxa yenkinga yokuqina nokuqina okungenamandla kwempushana ye-WC elula, ngokuvamile kuyadingeka ukwengeza inani elifanele le-binder njenge-cobalt (Co), i-nickel (Ni), i-chromium (Cr), i-molybdenum (Mo), i-titanium ( Ti), ithusi (Cu) nezinye izakhi lapho kwenziwa amathuluzi e-carbide aphelele okusebenza.

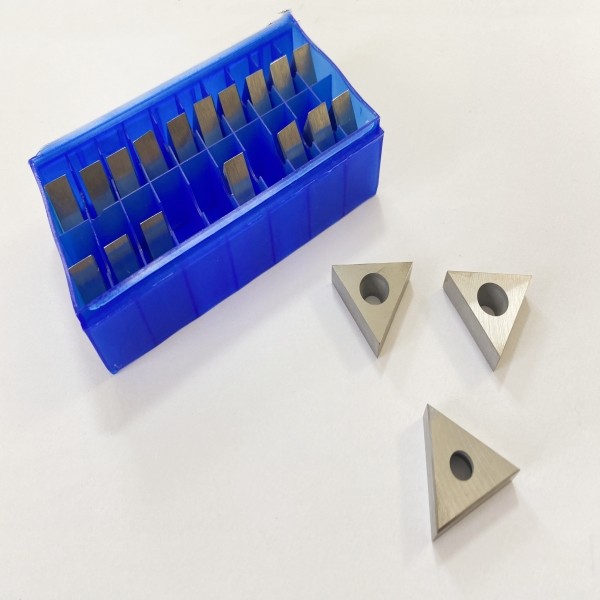

Ngokuqondile, nge-WC powder njengesigaba esinzima kanye ne-Co njengesigaba se-binder sifaneleka kakhulu kumathuluzi okusika.Ine-conductivity enhle yokushisa, okulungile ukusika ukuchithwa kokushisa okuvela esihlokweni sethuluzi, ukunciphisa izinga lokushisa lephuzu nokugwema ukushisa ngokweqile nokuthambisa ithiphu lethuluzi;inamandla aphezulu okuguquguquka kanye nokuqina komthelela, okunganciphisa ngempumelelo amathuba okuqhekeka lapho usikwa;inokumelana okuhle kakhulu kokusika (okungaphezulu kakhulu kwensimbi enesivinini esikhulu), futhi ingagaya unqenqema olucijile.

i-carbide blade enosimendenge-WC powder njengesigaba esinzima kanye ne-Ni njengesigaba sokubopha sifaneleka kakhulu izingxenye ezimelana nokugqwala.Ukumelana nokugqwala kwayo kunamandla ukwedlula amathuluzi e-tungsten ne-cobalt carbide, okuyenza ifaneleke ukusetshenziswa ezindaweni ezinemithombo yezindaba eyonakalisayo.Ngaphezu kwalokho, izigxivizo ze-WC-Ni ezifakwe usimende ze-carbide nazo zilungele ukusetshenziswa ekushiseni okuphansi, izinga lokushisa eliphezulu, i-vacuum nokucindezela okuphezulu.

I-WC, i-TiC ne-Co inezici zobulukhuni obuphezulu, ukumelana nokushisa okuhle, amandla aphezulu okucindezela, ukumelana ne-oxidation enhle, ukungahambi kahle kwe-thermal nokunye, okulungele ukucubungula insimbi.

Kumele kuqashelwe ukuthi izinkomba ezithile zomzimba zeingxubevange eqinileizoshintsha ngenani elihlukile lezinto zokusetshenziswa.Uma ungqimba noma izingqimba eziningi ze-carbide, i-carbide nezinye izinhlanganisela ezinzima eziphikisayo zifafazwa ebusweni be-alloy eqinile, ukumelana nokugqoka okuphezulu kanye nokuqina okuphezulu kwe-alloy kuzohambisana nakakhulu, ngakho-ke kufaneleka kakhulu ukusika ngesivinini esikhulu. .

Isikhathi sokuthumela: May-02-2023