Ukushiswa ngemuva kusho indlela yokuphinda igobe imikhiqizo eyonakele, engenisiwe, ekhishwe i-carburized kanye.imikhiqizo ye-tungsten carbidenge-pores ngokweqile.(1) Ukubuyiselwa emuva kwemikhiqizo engenisiwe futhi ekhishwe i-carburized.I-Carburizing kanye nokushiswa kwe-back-burn ngokuvamile kusebenzisa izinhlayiya ze-graphite ezisezingeni eliphezulu noma ingxube yezinhlayiya ze-graphite kanye ne-Al2O3 powder njengendlela ephakathi, futhi kuqhume ukushisa emuva ngaphansi kokuvikelwa kwe-hydrogen.

I-Decarburization kanye ne-backburning ngokuvamile zisebenzisa i-Al203 powder calcined at high temperatures noma ingxube ye-Al203 powder kanye ne-W powder ecolekileyo njenge-medium, futhi i-backburning yenziwa ngaphansi kokuvikelwa kwe-hydrogen.

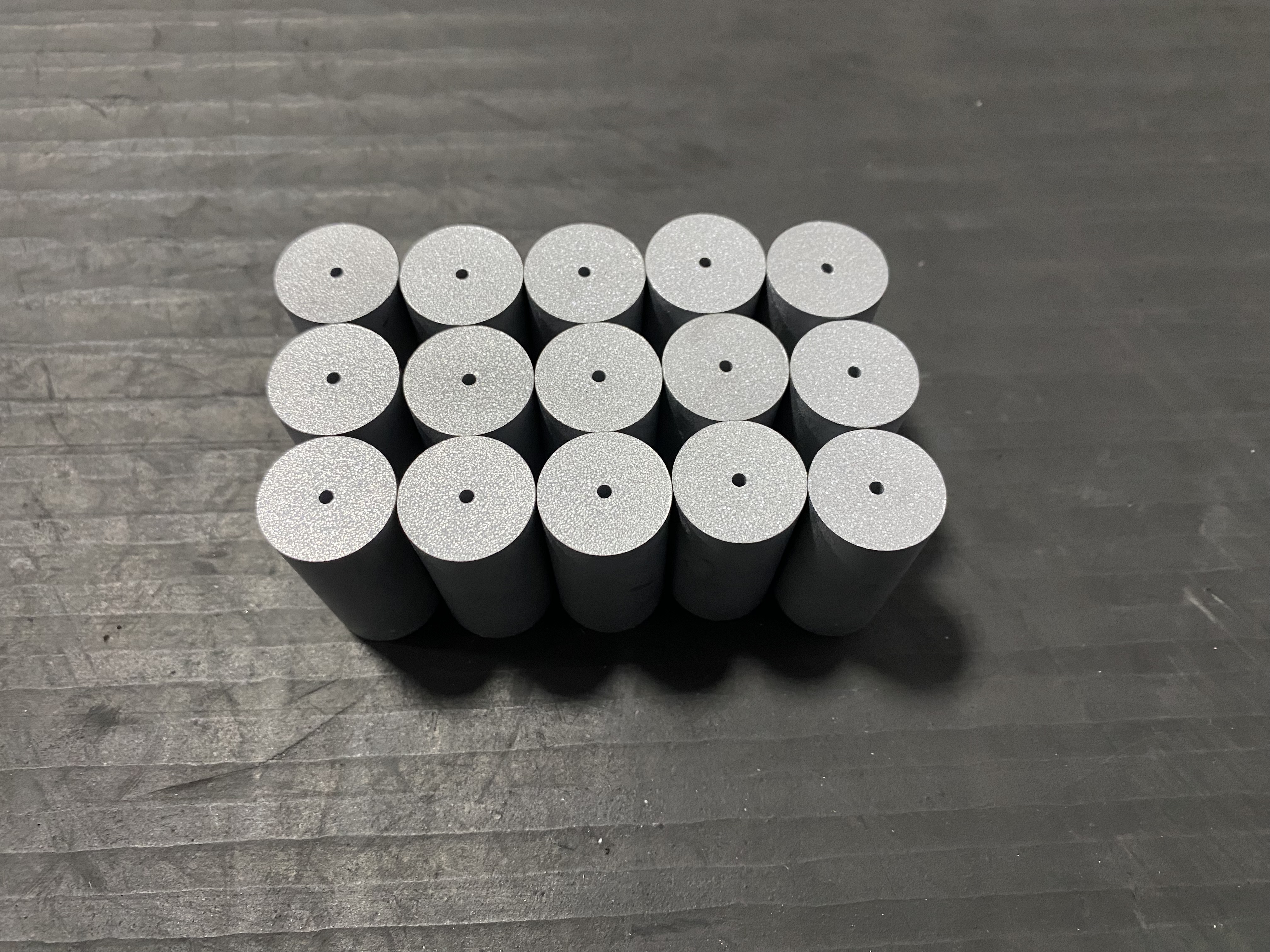

(2) I-porosity idlula izinga futhi ivutha emuva.Uma i-porosity ye-tungsten carbideimikhiqizo ye-sintered (izimbotshana ezingekho ezinkulu kuno-25 μm) idlula izinga, isithando somlilo esishisayo singasetshenziselwa ukucwilisa ingcindezi ngengcindezi engaba ngu-10MPa.Izinga lokushisa le-sintering kufanele libe ngu-20 ° C ngaphansi kwezinga lokushisa lokuqala lomkhiqizo.Ukucubungula ngezingcindezi eziphakeme kusetshenziswa ukucindezela kwe-isostatic okushisayo kusebenza kakhulu.

(3) Ukuqondisa.Ukubuyisela emuva kwenziwa ngokufaka ingcindezi nokusebenzisa ukuvikelwa kwe-hydrogen noma isimo se-vacuum ekushiseni okungaphezulu kancane kunokushisa kwe-eutectic.Isisindo esicindezelayo singalungiswa noma izinga lokushisa lokulungiswa linganyuswa ngokuvumelana nesimo sokulungiswa komkhiqizo, kodwa izinga lokushisa lokulungiswa akufanele libe ngaphezu kwezinga lokushisa lokuqala lomkhiqizo.

Isikhathi sokuthumela: Jan-07-2024