1. Izici zomqondo

I-carbide enosimendeingxubevange yensimbi yensimbi efana ne-tungsten carbide (WC) powder kanye nensimbi ebophayo efana ne-cobalt powder, ebizwa nge-Tungsten Carbide/Cemented Carbide ngesiNgisi, okuqukethwe kwayo kwe-carbide ephezulu lokushisa kungaphezu kwalokho kwensimbi enesivinini esikhulu. .

Insimbi enesivinini esiphezulu yakhiwe ngenani elikhulu le-tungsten, i-molybdenum, i-chromium, i-cobalt, i-vanadium nezinye izakhi zensimbi ene-carbon high-alloy steel, ikakhulukazi eyakhiwe ngensimbi yensimbi (njenge-tungsten carbide, i-molybdenum carbide noma i-vanadium carbide) nensimbi. i-matrix, okuqukethwe kwekhabhoni okungu-0.7% -1.65%, inani eliphelele lama-elementi e-alloying lifika ku-10% -25%, igama lesiNgisi le-High Speed Steels (HSS).

2, ukusebenza

Bobabili banobunzima obukhulu, amandla aphezulu, ukuqina okuhle, ubulukhuni obomvu, ukumelana nokugqoka, ukumelana nokushisa nokusebenza kwenqubo, njll., futhi zonke lezi zici zizohluka ngenxa yamabanga ahlukene.Ngokuvamile, ubulukhuni, ubulukhuni obubomvu, ukumelana nokushisa nokumelana nokushisa kwe-carbide enosimende kungcono kune-HSS.

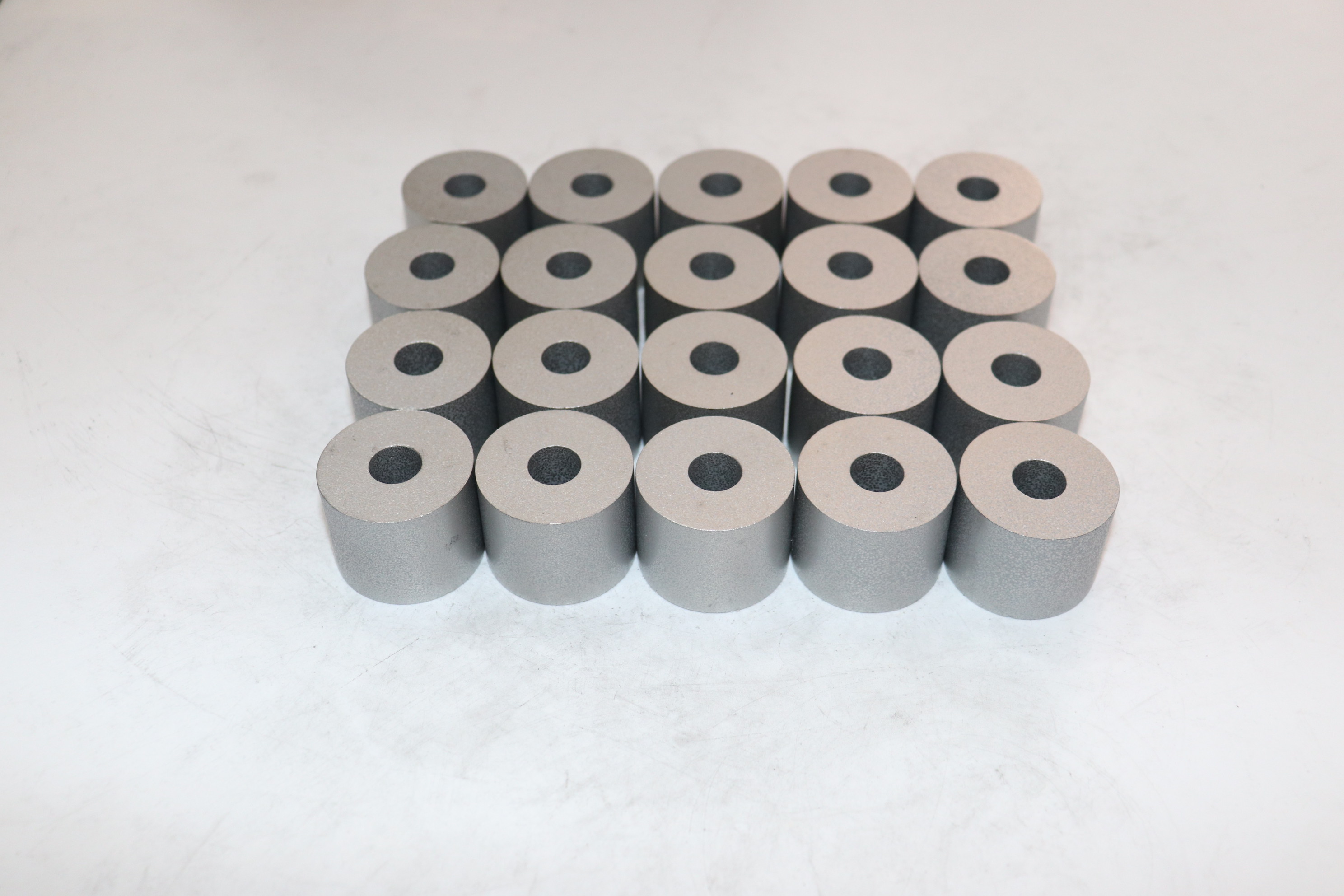

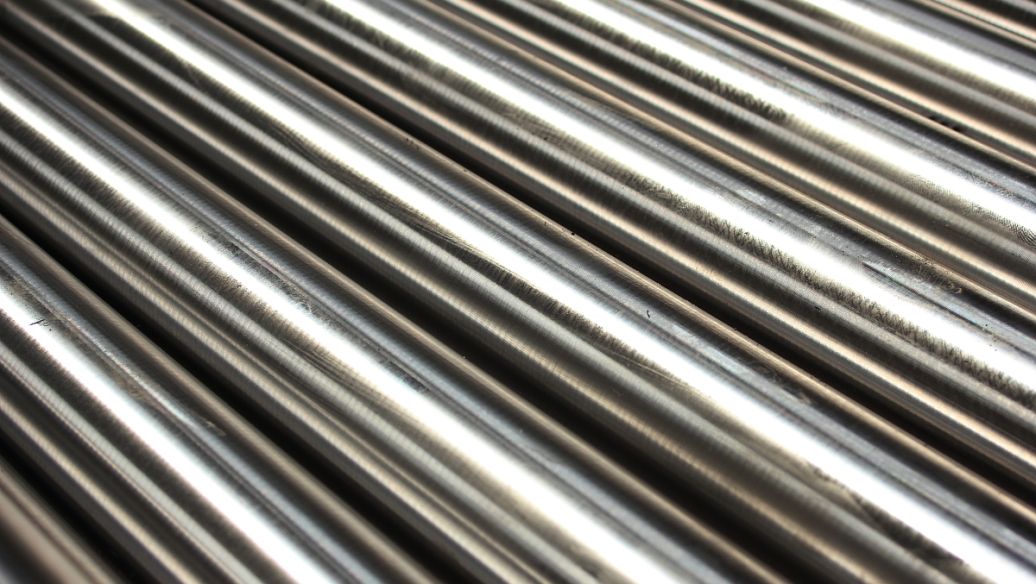

3, inqubo yokukhiqiza

Inqubo yokukhiqiza ye-carbide enosimende ikakhulukazi ihlanganisa inqubo ye-powder metallurgy, ubuchwepheshe bokubumba umjovo noma inqubo yokuphrinta ye-3D.

Izindlela zokukhiqiza zensimbi enesivinini esikhulu zihlanganisa ubuchwepheshe bokuphonsa bendabuko, ubuchwepheshe bokubuyisela kabusha i-electroslag, ubuchwepheshe be-powder metallurgy kanye nobuchwepheshe bokubumba umjovo.

4, izicelo

Nakuba bobabili bangenza amathuluzi, isikhunta somsebenzi oshisayo kanye nesikhunta somsebenzi obandayo, banezakhiwo ezahlukene.Amathuluzi e-carbide avamile anesivinini sokusika esiphindwe izikhathi ezingu-4 kuya kwezingu-7 nempilo ephakeme izikhathi ezi-5 kuya kwezingu-80 kunamathuluzi e-HSS avamile.Mayelana nokusetshenziswa kwamathuluzi, impilo ye-carbide tooling iphakeme ngokuphindwe izikhathi ezingama-20 kuye kweziyi-150 kunaleyo ye-HSS tooling, isibonelo, impilo yesihloko esishisayo ne-extrusion die eyenziwe ngensimbi engu-3Cr2W8V iyizikhathi eziyizigidi ezingu-0.5, nempilo yesihloko esishisayo ne-extrusion. ukufa okwenziwe nge-YG20 carbide izikhathi eziyi-150,000.

Isikhathi sokuthumela: May-11-2023