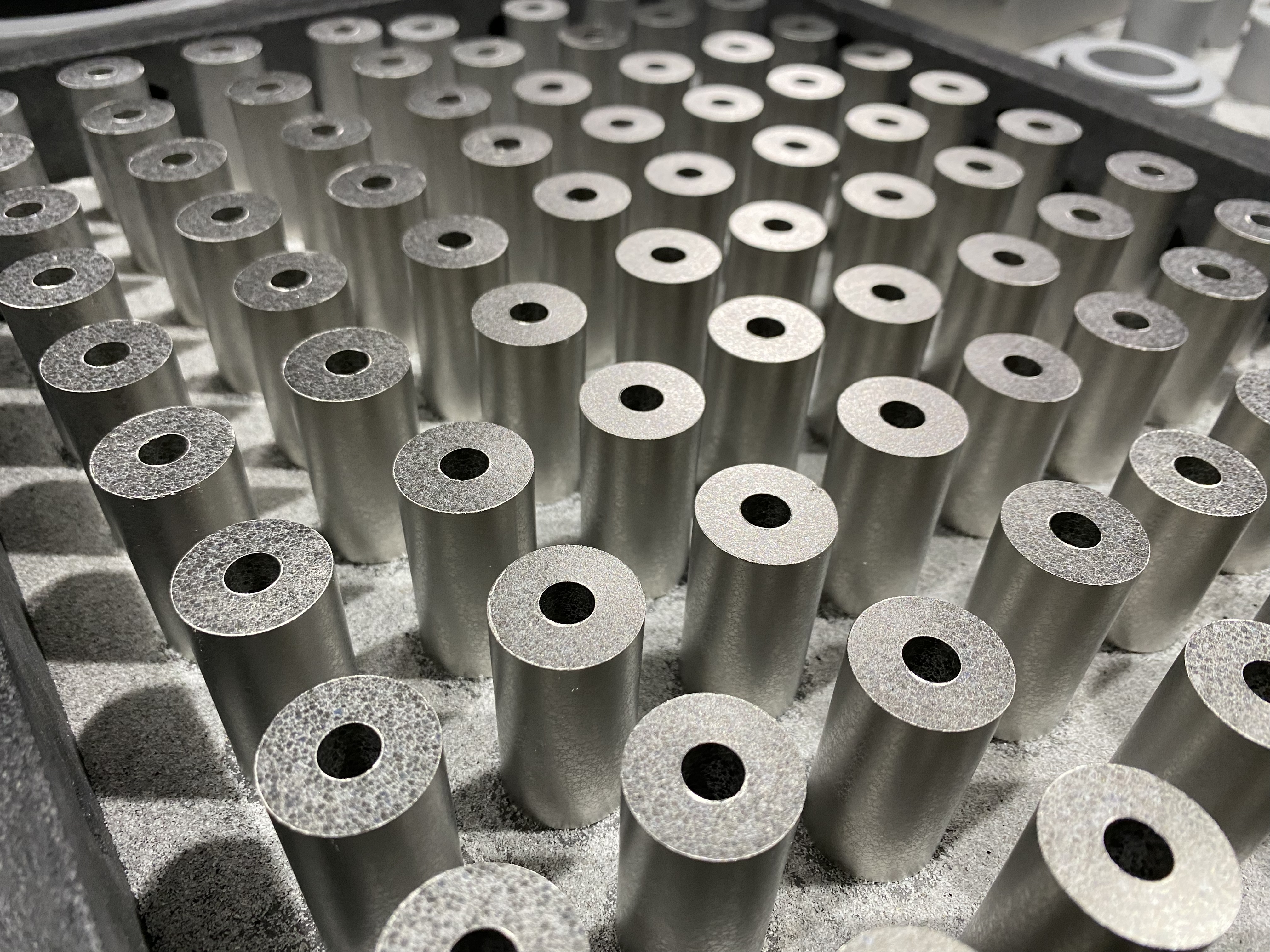

Izihloko ezibandayo ziyisikhunta sokucubungula isihloko esibandayo, ngokuvamile esenziwe ngensimbi enesivinini esikhulu, insimbi yensimbi eyingxubevange, ingxubevange eqinile nezinye izinto.Isihloko esibandayo siyinqubo yokwenza insimbi lapho okubalulekile kwensimbi kucindezela futhi kukhishwa ngama-dies amaningi ukuze kuzuzwe inqubo ethile yokucubungula nosayizi.Amafa esihloko esibandayo ngokuvamile akhiwa izingxenye eziningi, futhi umumo nosayizi wesigaba ngasinye kuyahlukahluka kuye ngomkhiqizo odingekayo.Imikhiqizo yesihloko esibandayo esivamile ihlanganisa izintambo ezihlukahlukene, amaphinikhodi nezingxenye ezincane zobubanzi.

Isihloko esibandayo se-Tungsten carbide siyafa ngokuvamile sikhiqizwa inqubo yokucindezela eshisayo ye-isostatic.Izinga lokushisa le-sintering lincike ikakhulukazi ezintweni ezibonakalayo kanye nokwakheka kwamakhemikhali e-tungsten carbide powder, kanye nezimo ze-sintering ezisetshenziswayo.Ngokuvamile, izinga lokushisa le-sintering le-tungsten carbide cold heading die lingaphezulu kuka-1500°C, futhi ukukhethwa kwezinga lokushisa elithile nakho kudinga ukucabangela izidingo zokuklama kanye nenqubo yokukhiqiza idayizi.Uma izinga lokushisa le-sintering liphezulu kakhulu, isakhiwo sesikhunta sizokhubazeka, futhi uma izinga lokushisa le-sintering liphansi kakhulu, kuyoba nzima ukuthola amandla anele nokumelana nokugqoka.Ngakho-ke, ukukhethwa kwezinga lokushisa le-sintering kudinga ukucabangela izici ezihlukahlukene ngokugcwele ukuze kuqinisekiswe ukusebenza okuhle nempilo yesevisi yesihloko esibandayo se-tungsten carbide siyafa.

Isikhathi sokuthumela: May-21-2023