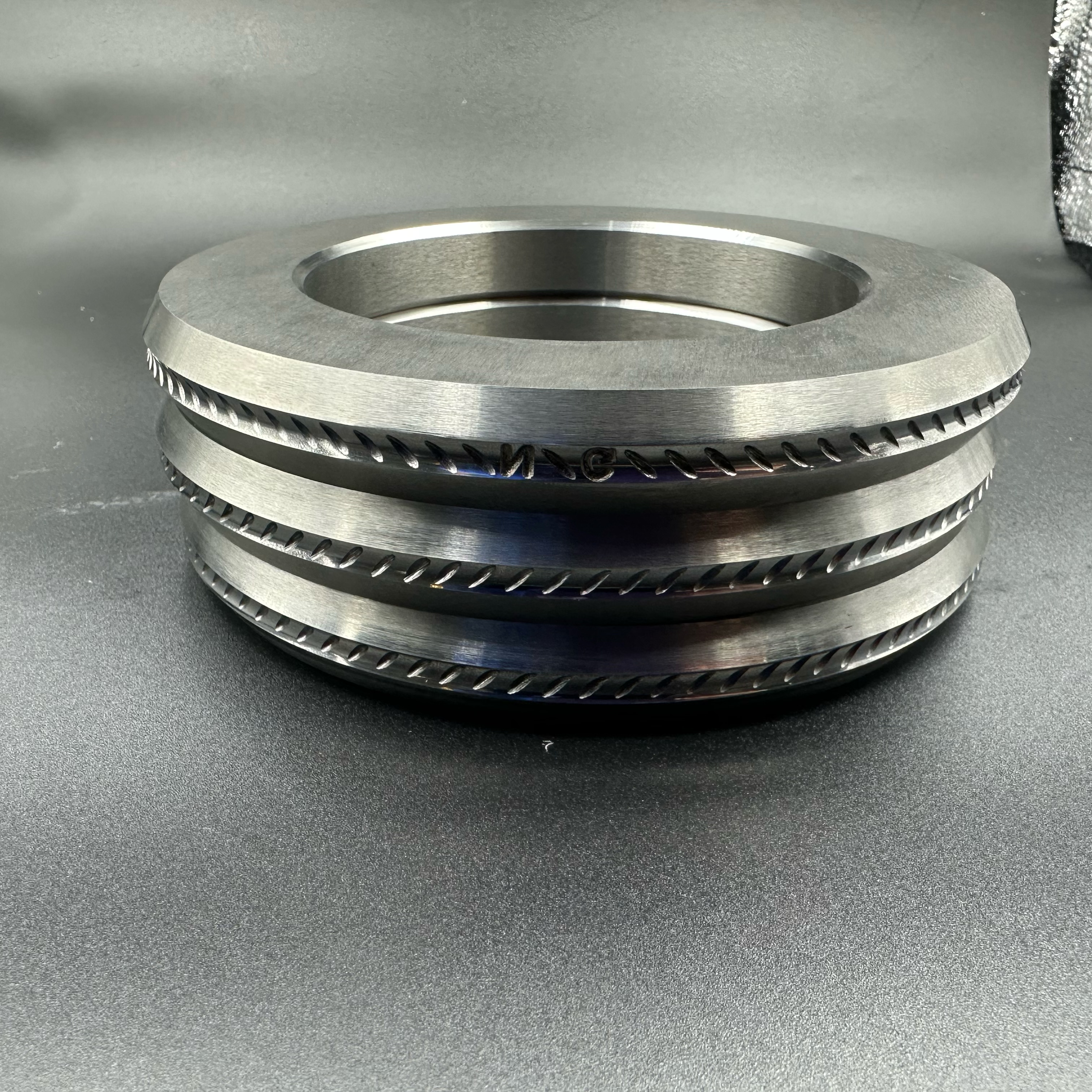

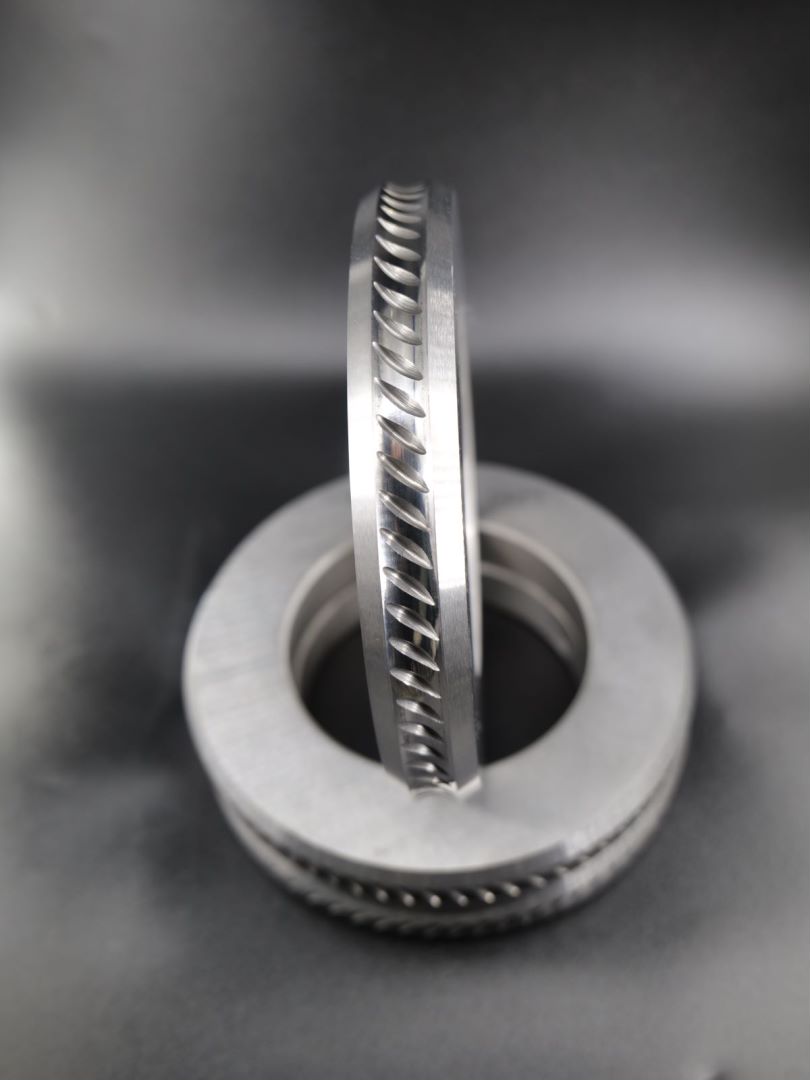

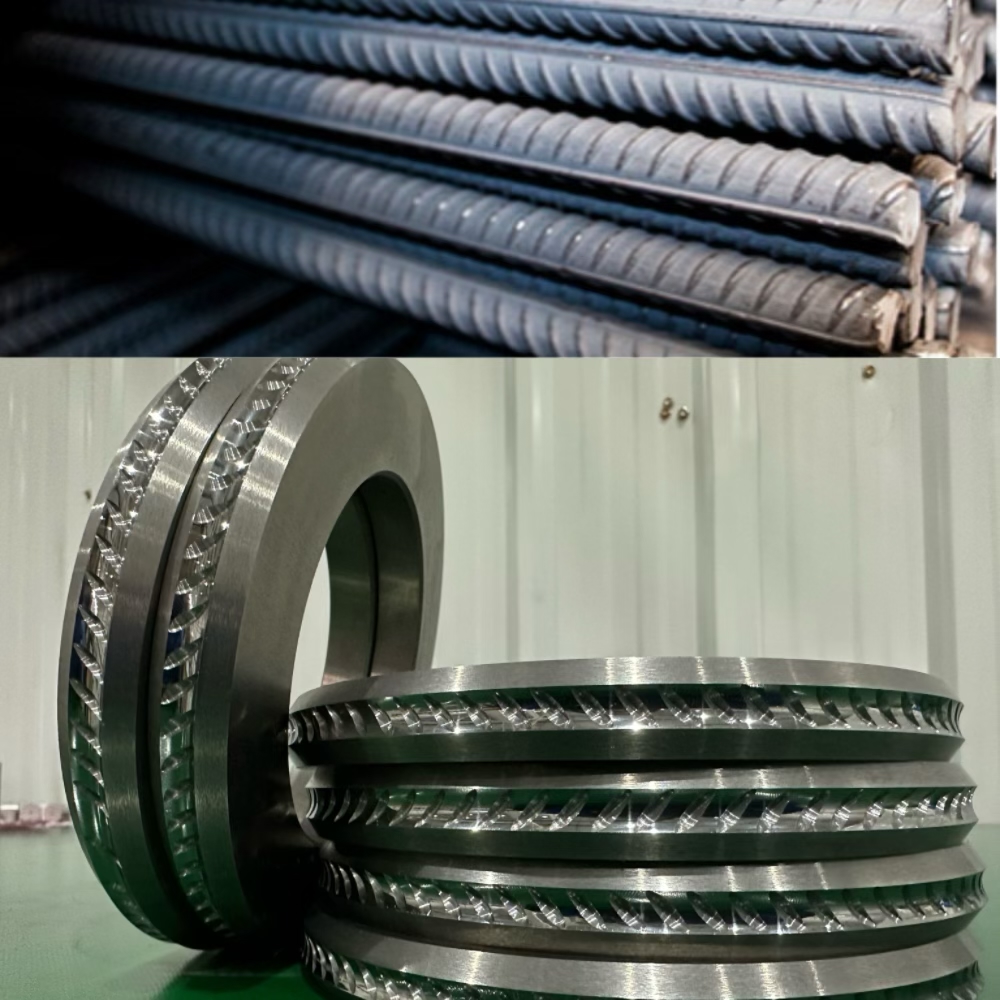

I-Carbide rollerizindandatho ziyizinto zamathuluzi ezinobulukhuni obuphezulu kanye nokumelana nokugqoka okuphezulu okuhlanganiswe ne-tungsten carbide nensimbi eboshiwe.Izindandatho ze-carbide roller kufanele zinikeze ukudlala okugcwele ekuqineni kwabo kokugqokwa okuphezulu, impilo ende kanye nokumelana nokugqoka okuphezulu ekugoqeni kwenduku yocingo enesivinini esikhulu.Izinzuzo zokusebenza kahle, lapho ufaka, sidinga ukunaka izinto ezilandelayo:

1. Amarola afanayo: Umehluko wobubanzi wamarola afanayo kuhlaka olufanayo kufanele ube ngu-0, ungeqi ukuhlanganisa noma ukususa u-0.05mm

2. Ngaphambi kokufaka i-i-carbide roller, indandatho ye-roller kanye nomkhono we-taper kufanele kugcinwe ekushiseni okungashintshi okungama-25-30 degrees Celsius.Ngesikhathi esifanayo, uthele amanzi ashisayo ku-roller shaft, noma uyiqhube idling imizuzu engu-20 ukuze uyishise kuqala.

3. Ukufakwa kwei-carbide rollerindandatho kanye nomhlangano emshinini wenziwa ngokuqinile ngokuvumelana nokunemba okudingekayo ngenqubo yokuklama.Iringi ye-roller, i-frame roller shaft kanye nomkhono we-taper kufanele kube nokulingana okulungile futhi akufanele kuqine kakhulu noma kukhululeke kakhulu.

4. Ngaphambi kokusebenzisa umshini, hlola ukuthi indandatho ye-roller iyahlangabezana yini nezidingo, futhi izindawo zokuhlangana zendandatho ye-carbide roller, umkhono we-taper, kanye ne-shaft kufanele kukhuhlwe ngokucophelela.Kuvinjelwe ngokuphelele ukusebenzisa isando noma enye into eqinile ukuze ungqongqoze indandatho ye-roller lapho usebenzisa umshini, ngesikhathi sokuthutha, nokufakwa.Kwenqatshelwe ngokuphelele ukungqubuzana phakathi nenqubo ukuvimbela ukulimalaroller izindandatho.

Isikhathi sokuthumela: Mar-24-2024