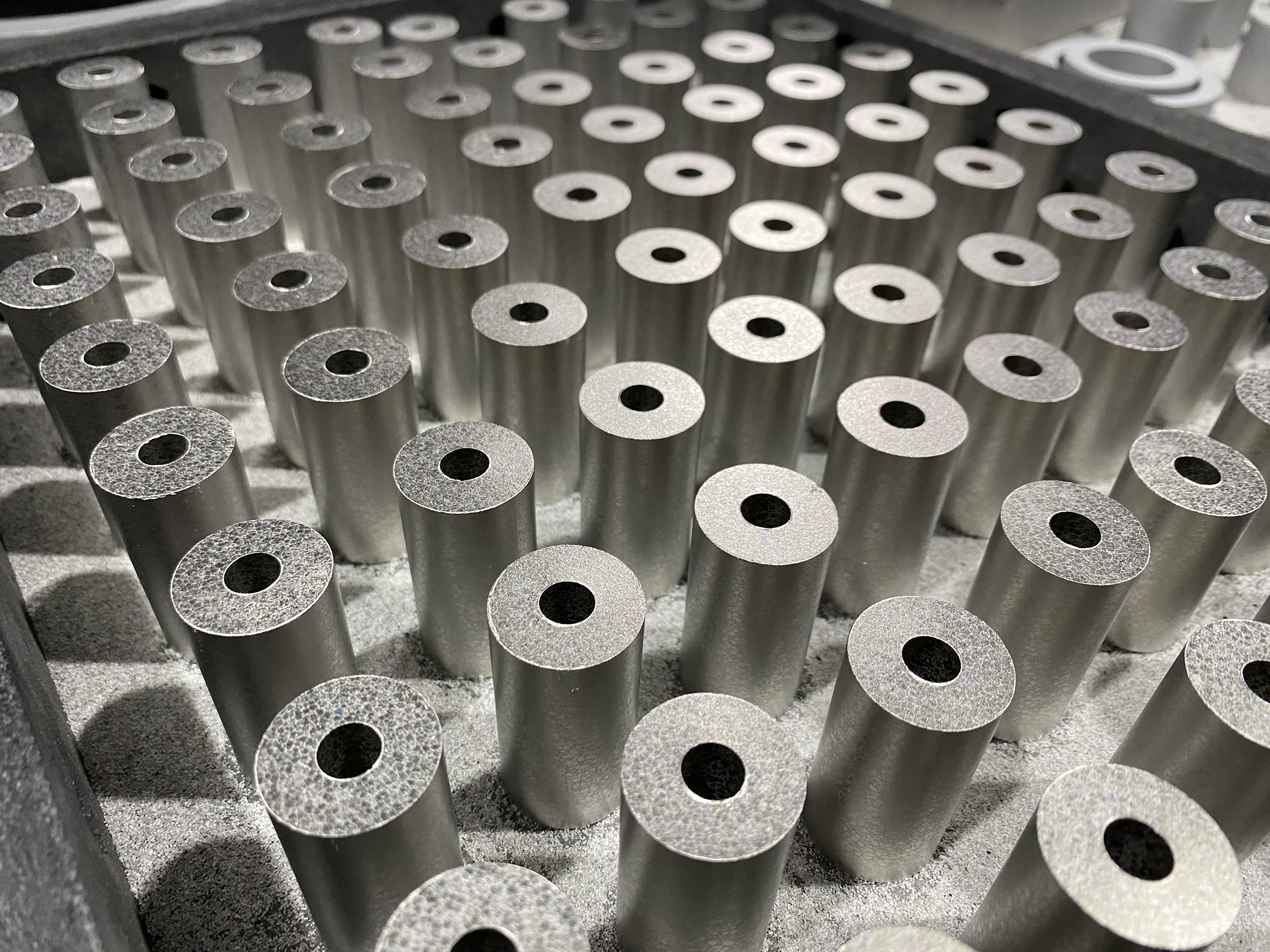

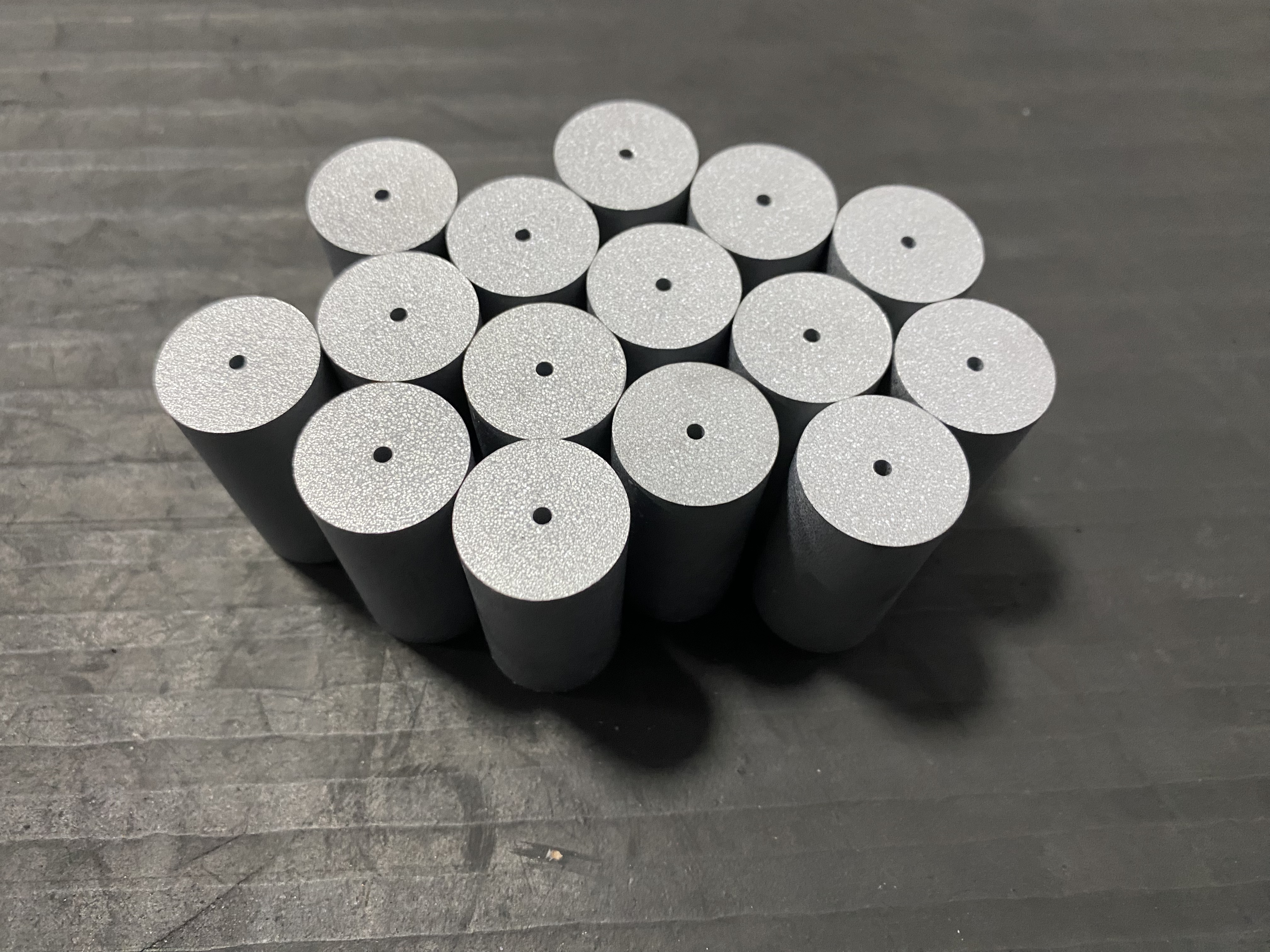

I-carbide enosimendeukubumba kuwukuhlanganisa impushana exubile ukuze uthole ukuminyana okudingekayo nokufana kokuqina, kanye nesimo esidingekayo.

Inqubo yokukhiqiza izimo ezihlangene kanye nokunemba kwe-dimensional idinga ukuthi into ehlangene kufanele ibe namandla athile.Ukuminyana okuhlobene kwe-compact ngokuvamile cishe ku-50%

Ngakwesokudla, ukuminyana okuhlangene kuphansi kakhulu futhi i-sintering ayikwazi ukuminyana ngokuphelele.Uma iphezulu kakhulu, ukucindezela akukwazi ukuqedelwa noma amaphutha anjengokubumbana okuhlangene nokuqhekeka kungenzeka.Ukwakha kuyinqubo esebenza kakhulu kusimendei-carbideukukhiqizwa futhi kuyinqubo ebalulekile yokuqinisekisa ukunemba, ikhwalithi esobala kanye nekhwalithi yangaphakathi yei-carbide engenalutho.Kunezindlela eziningi zokubumba ze-carbide enosimende, njengokubumba kokucindezelwa, ukubumba kwe-extrusion, ukubumba umjovo, ukubumba okubandayo kwe-isostatic pressing-cut, njll.

Phakathi kwazo, ukubumba kuyindlela esetshenziswa kakhulu futhi esetshenziswa kabanzi.Ukwakhiwa kwenetha okunembayo ukunemba kwemikhiqizo ye-carbide enosimende.izidingo zokuthuthukiswa kokukhiqiza.Izindlela ezihlukene zokubumba zinezakhiwo ezahlukene zemishini yokubumba kanye nesikhunta.Imikhiqizo enomumo oyinkimbinkimbi engakwazi ukwakheka ngokuqondile ngokucindezela, noma imikhiqizo usayizi weqoqo wayo mncane kakhulu futhi kungenamali ukwenza enye isethi yokubunjwa kokucindezela, yengezwe ngokucindezela imishini.

Isikhathi sokuthumela: Jan-05-2024