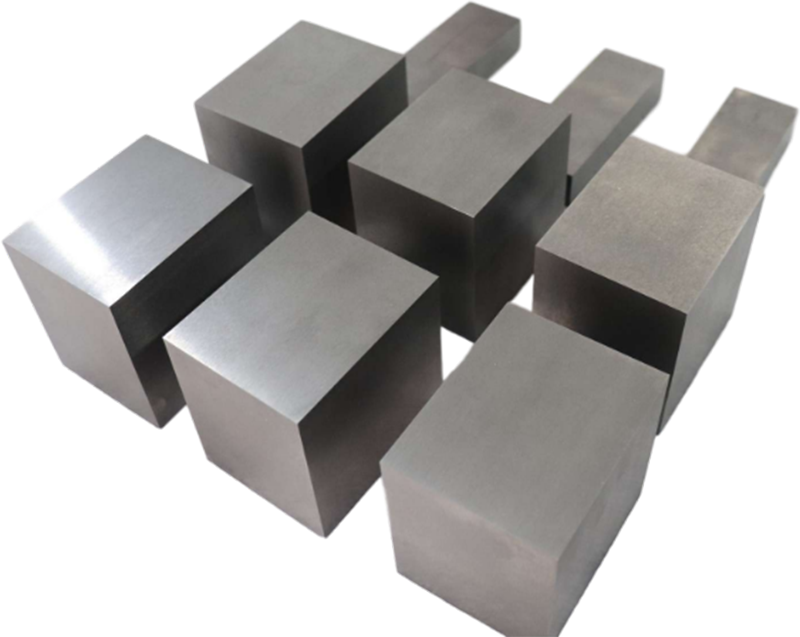

Ama-carbide anosimende enziwa ngokuxuba i-tungsten carbide ne-cobalt ngesilinganiso esithile, icindezela ibe yizimo ezihlukahlukene, bese i-semi-sintering.Le nqubo ye-sintering ngokuvamile yenziwa esithandweni somlilo.Ishiswa esithandweni sevacuum ekushiseni okungaba ngu-1,300 kuya ku-1,500 degrees Celsius.

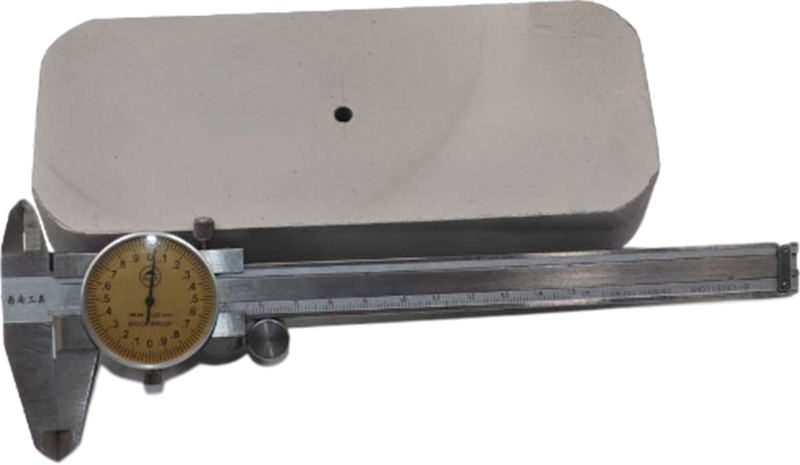

Ibha emise okukhethekile

I-Sintered hard alloy forming iwukucindezela impushana ibe yi-billet, bese ifakwa esithandweni somlilo esishisayo kuze kufike ezingeni lokushisa elithile (izinga lokushisa le-sintering), futhi ugcine isikhathi esithile (ukubamba isikhathi), bese upholisa phansi, ukuze uthole ukusebenza okudingekayo. i-hard alloy material.

Inqubo ye-cemented carbide sintering ingahlukaniswa ngezigaba ezine eziyisisekelo:

1: Ukususwa kwe-ejenti eyakha kanye nesiteji sokudubula, kulesi sigaba umzimba we-sintered ushintsha kanje:

Ukususwa kwe-ejenti yokubumba, esigabeni sokuqala sokucwilisa ngokukhuphuka kwezinga lokushisa, i-ejenti yokubumba ibola kancane kancane noma ihwamuke, ikhiphe umzimba osikiwe, ngasikhathi sinye, i-ejenti yokubumba icishe ifane ne-sintered body carburizing, inani le-carburizing lizoshintsha. ngohlobo lwe-ejenti yokubumba, inombolo kanye nenqubo ehlukile yokuhlanganisa.

Ama-oxide angaphezulu empushana ayancishiswa.Ezingeni lokushisa elishisayo, i-hydrogen inganciphisa ama-oxide e-cobalt ne-tungsten.Uma i-ejenti yokwakha ikhishwa ku-vacuum futhi ifakwe i-sintered, ukusabela kwe-carbon-oxygen akunamandla.Ukucindezeleka kokuxhumana phakathi kwezinhlayiya ze-powder kuqedwa kancane kancane, i-powder yensimbi ebophezelayo iqala ukubuyisela futhi ihlaziye kabusha, ukusabalalisa kwendawo kuqala ukwenzeka, futhi amandla e-block athuthukiswa.

2: isigaba esiqinile se-sintering (800 ℃- izinga lokushisa le-eutectic)

Ezingeni lokushisa ngaphambi kokuvela kwesigaba se-liquid, ngaphezu kokuqhubeka nenqubo eyenzeka esigabeni sangaphambilini, ukusabela okuqinile nokusabalalisa kuyaqina, ukugeleza kwepulasitiki kuyathuthukiswa, futhi umzimba we-sintered ubonakala uncipha ngokusobala.

3: isigaba se-liquid sintering stage (izinga lokushisa le-eutectic - ukushisa kwe-sintering)

Uma kunesigaba se-liquid emzimbeni we-sintered, i-shrinkage iqedwa ngokushesha, bese kwenzeka ukuguqulwa kwe-crystallization, okwenza i-microstructure eyisisekelo kanye nesakhiwo se-alloy.

4: isigaba sokupholisa (izinga lokushisa le-sintering - izinga lokushisa legumbi)

Kulesi sigaba, ukwakheka kwe-microstructure kanye nesigaba se-alloy kushintsha nezimo zokupholisa ezihlukene, ezingasetshenziswa ukushisa ukwelashwa kwe-carbide enosimende ukuze kuthuthukiswe izakhiwo zayo ezingokwenyama nezomshini.

Isikhathi sokuthumela: Feb-10-2023