Ake siqale ngemishini yokucubungula:

I-1, i-groove yangaphakathi, imbobo, izintambo zangaphakathi nezangaphandle kanye nezinye izinto zokusebenza zokucubungula: ngalezi zici zomumo, ngokuvamile sifuna ukusebenzisa ithuluzi elikhethekile lomshini we-CNC - umshini wokudweba nge-ceramic kanye nomshini wokugaya, leli thuluzi lomshini libonakala lihlobene ngokoqobo. izitsha zobumba, empeleni, leli thuluzi lomshini liyasebenza nasekucutshungulweni kwe-carbide enosimende.Ngoba lapho kucutshungulwa i-carbide, kuzokwenziwa uthuli olwengeziwe, futhi ukulimala kwalezi zintuli ethuluzini lomshini kusekubi kakhulu.I-CNC yendabuko inzima ukumelana nalezi zintuli ezinhle, ngaleyo ndlela kuholela kalula ekugugekeni nasekudabukeni kwesikulufu kanye nezinye izingxenye.Umshini oqoshiwe we-ceramic kanye nomshini wokugaya ungaxazulula lesi simo kahle kakhulu, ngoba umshini wokuqopha i-ceramic nomshini wokugaya unezinyathelo zokuvikela eziphelele kakhulu, ezingahlukanisa kahle i-carbide powder ezingxenyeni eziqondile.

2, Imishini yokucubungula izindiza nezinyathelo: Lapho ucubungula izindiza ezinkulu nezinyathelo phezului-carbideizinto zokwakha, kungcono ukusebenzisa izigayi ezingaphezulu, ezinokunemba okuphezulu kokucubungula nokusebenza kahle.

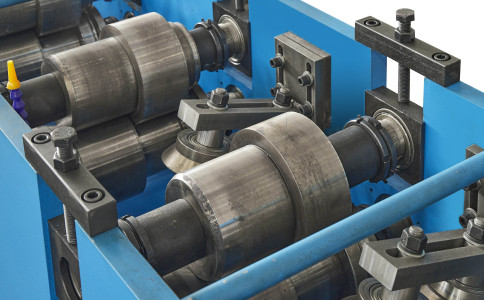

3, Imishini yokucubungula yendilinga yangaphandle: umshini wokugaya wangaphandle, umshini wokugaya ongenalutho, njll. ingasetshenziswa lapho kucutshungulwa indilinga yangaphandle ye-carbide.

Izindlela zokukhiqiza zei-carbide enosimende:

I-1, Ukwenziwa kwezintambo zangaphakathi nezangaphandle: Ukucutshungulwa kwentambo ye-carbide enosimende kufanele kucutshungulwe ngokugaya intambo, hhayi ngokuthepha ngokuqondile.

I-2, Ukucutshungulwa kwe-groove yangaphakathi: induku yokugaya idayimane kufanele isetshenziswe, futhi inani le-undercutting lilawulwa yizintambo ezingaba ngu-2-3 isikhathi ngasinye, okufanele zilungiswe ngokuvumelana nezinzuzo kanye nobubi benduku yokugaya idayimane.

3, Umshini wokukhipha ugesi (ocingweni, ucingo oluhamba kancane, ukucutshungulwa kwezintambo ezihamba ngokushesha)

4, Welding processing: ithusi Welding, isiliva Welding processing.

5, Ukugaya ukucubungula: ukugaya okungenasikhungo, ukugaya kwangaphakathi, ukugaya indiza, ukucubungula ithuluzi lokugaya, isondo lokugaya elisetshenziswa ngokuvamile isondo lokugaya idayimane, kuye ngezidingo zenqubo yokukhetha.

I-6, i-Laser processing: i-laser cutting and forming, i-punching, kodwa ubukhulu bokusika buboshwe ngamandla omshini we-laser.

Isikhathi sokuthumela: Jun-22-2023