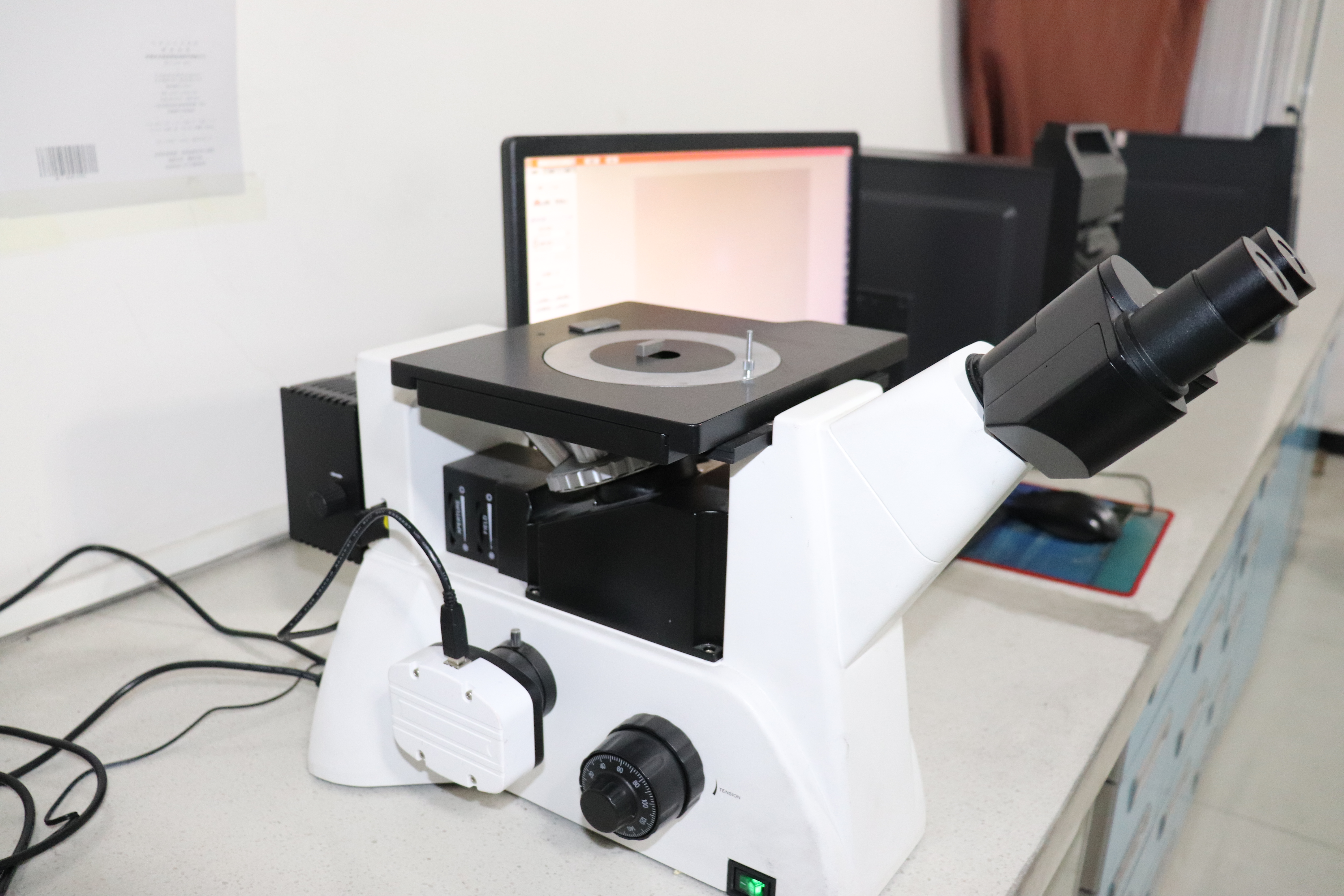

I-Metallographic microscope iyithuluzi lokuhlola impahla yensimbi evame ukusetshenziswa, engasetshenziswa ukutadisha i-microstructure, ukwakheka nokusebenza kwe-carbide enosimende.Nazi ezinye izibonelo ze-metallurgical microscopy ekufakweni kwe-carbide enosimende: 1. Ukuhlaziywa kwe-Microstructure: Isibonakhulu se-Metallographic singakwazi ukubona i-microstructure ye-carbide enosimende, okuhlanganisa ukuma okusanhlamvu, usayizi wokusanhlamvu, i-morphology yomngcele wokusanhlamvu nokusabalalisa, njll. Lokhu kubaluleke kakhulu ekuqondeni izakhiwo. kwei-carbide enosimendekanye nezinguquko ngesikhathi somshini.2. Ukuhlaziywa kokwakheka kwamakhemikhali: I-carbide enosimende ivamise ukwakhiwa ngezinto ezihlukahlukene zensimbi nezingezona ezensimbi.Isibonakhulu se-metallographic singanquma indawo nokusabalalisa kwento ngayinye ku-carbide enosimende esakhiweni esincane kanye nokuqukethwe okuhlobene kwezingxenye zekristalu ngobuchwepheshe bokuhlaziya i-chemical probe.

3. Ukuhlaziywa kokuguqulwa kwesigaba nokuziphatha kokwenziwa kabusha kwekristalu:I-carbide enosimendeingase ibhekane nokuguqulwa kwesigaba kanye nokuziphatha kabusha kwekristalu ngesikhathi sokucubungula nokusetshenziswa.I-metallographic microscopy ingabuka futhi ihlaziye lezi zindlela zokuziphatha ukuze iqonde izinguquko ezimpahleni ezincane ze-carbide enosimende.4. Ukuhlaziywa kokukhubazeka nokulimala: I-carbide enosimende ingase yonakaliswe ngesikhathi sokusetshenziswa, njengokuqhekeka, ukukhathala, njll. I-microscopy ye-Metallographic ingabona amaphutha kanye nomonakalo ku-carbide enosimende futhi ihlaziye indlela yokwakheka kwayo.Sengiphetha, i-microscopy ye-metallographic iyithuluzi elibalulekile lokutadisha izakhiwo kanye nezinguquko zesakhiwo se-carbide enosimende.Ngokubheka i-microstructure kanye nokwakheka kwamakhemikhali e-carbide enosimende, singathola ukuqonda okujulile kokusebenza nokuziphatha kwayo, bese siqondisa ukulungiswa nokusetshenziswa kwe-carbide enosimende.

Isikhathi sokuthumela: Jun-08-2023