Ama-hard alloys e-WC-Co anokuguquguquka okuhle kwe-microwave.Phakathi nenqubo ye-sintering, izindlela zokulahlekelwa ezisebenza endaweni yezinga lokushisa eliphansi ngokuyinhloko ukulahlekelwa ukukhululeka kwe-polarization kanye nokulahlekelwa kazibuthe, kuyilapho endaweni yokushisa ephezulu ingxubevange imunca amandla e-microwave.Ikakhulukazi ngendlela yokulahleka kwe-dielectric kanye nokulahleka kwe-conductivity.

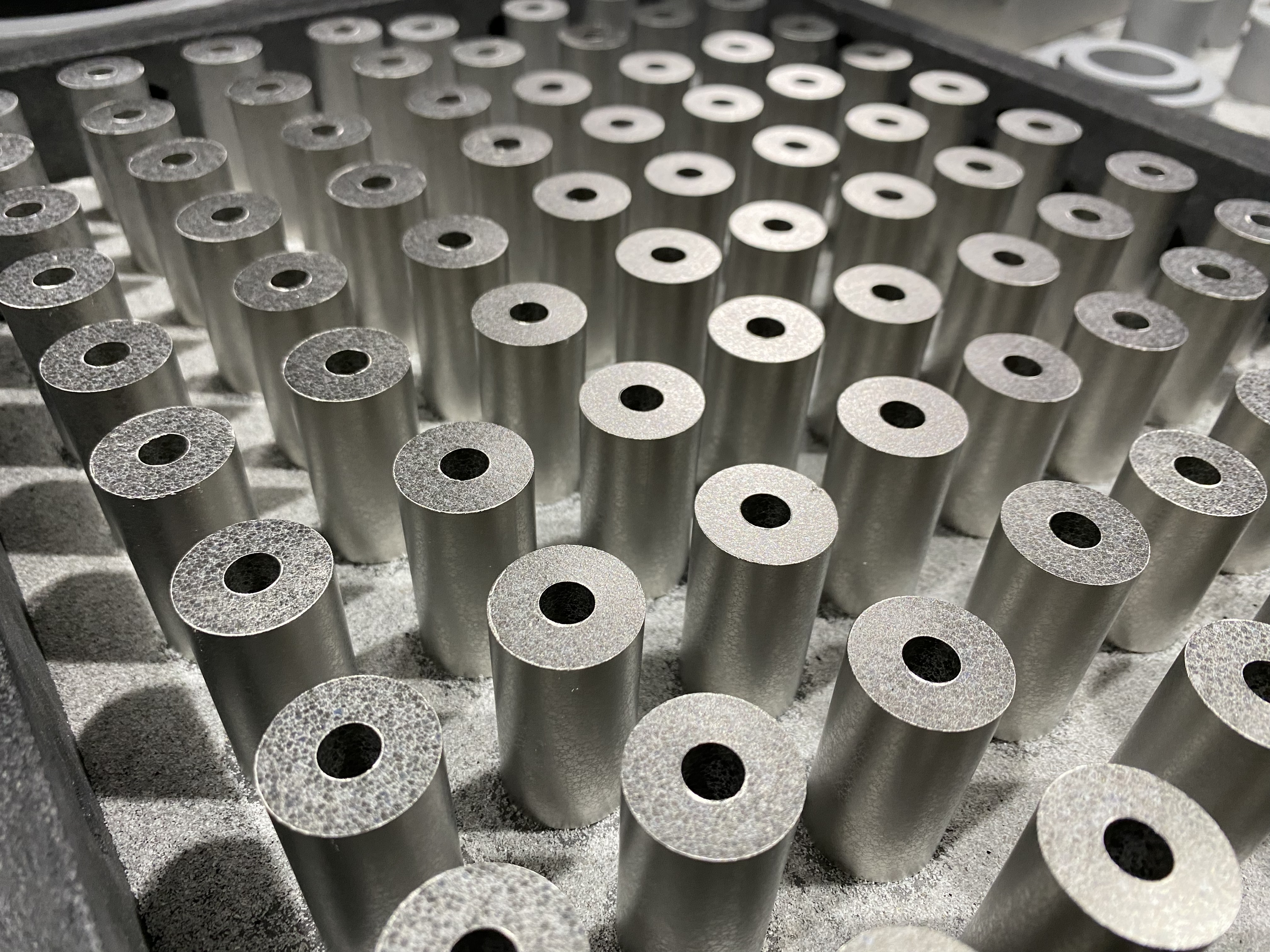

Iingxubevangengokwengezwa kwe-0.4% VC kanye no-0.2% Cr3C2 (ingxenyana yobuningi) njengezisetshenziswa ezisizayo zinokusebenza okungcono kakhulu;ukusetshenziswa kwe-vacuum microwave sintering kuthuthukisa kakhulu ukusebenza kwe-alloy.Ukusebenzisa i-multi-cavity microwave sinteringI-WC-8Co, ishiswa ku-1400°C ngaphandle kokulondoloza ukushisa.Ukuminyana kungafinyelela ku-14.71g/cm, iI-HRA ifinyelela90.3, futhi isakhiwo siyafana.

Ubuchwepheshe be-Microwave sintering bungasetshenziswa ukulungisa ama-cermets amahle kakhulu anezinhlamvu ezinhle, ukwakheka okufanayo nokusebenza okuhle kakhulu.Njengoba izinga lokushisa le-sintering likhula, ukuncipha, ukuminyana, amandla okuguquguquka nobulukhuni be-ultra-fine cermets kuqala ukwanda bese kuncipha, ngenani eliphakeme elivela ku-1500 ° C;Inqubo efanelekile yokucwiliswa kwe-microwave kuma-ultra-fine cermets Ngemva kokugcinwa ku-1500°C imizuzu engu-30, amandla okuguquguquka nobulukhuni ngu-1547MPa no-90.6HRA ngokulandelana, anyuke ngo-24.0% no-0.7% ngokulandelanayo uma kuqhathaniswa nokucwiliswa okuvamile.

Isikhathi sokuthumela: Jan-03-2024