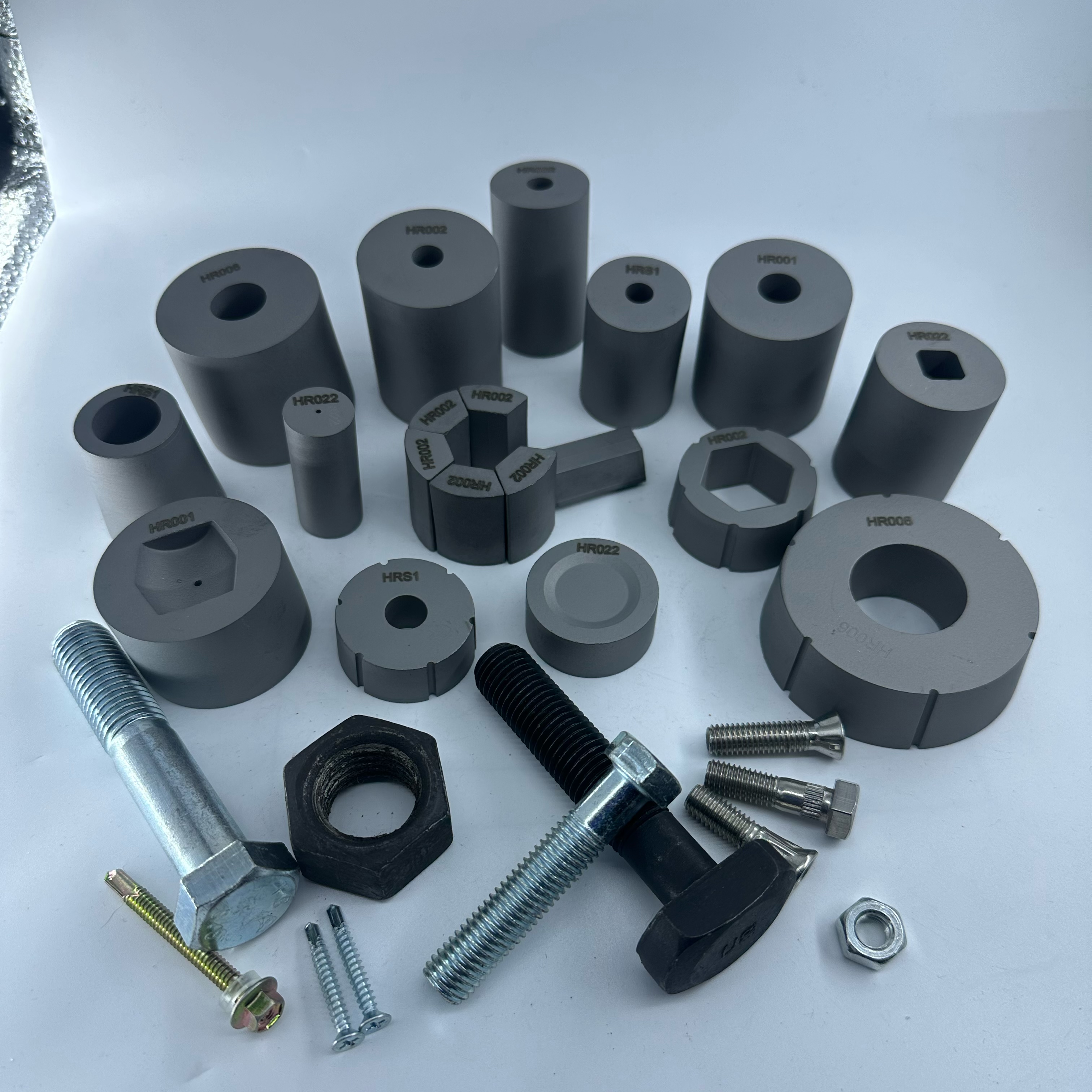

I-High Toughness Tungsten Carbide Cold Heading Dies / Cemented Carbide Heading Dies

1. Imboni yaseShayina ekhethekile ekucubunguleni nasekukhiqizeni, isitifiketi se-ISO.

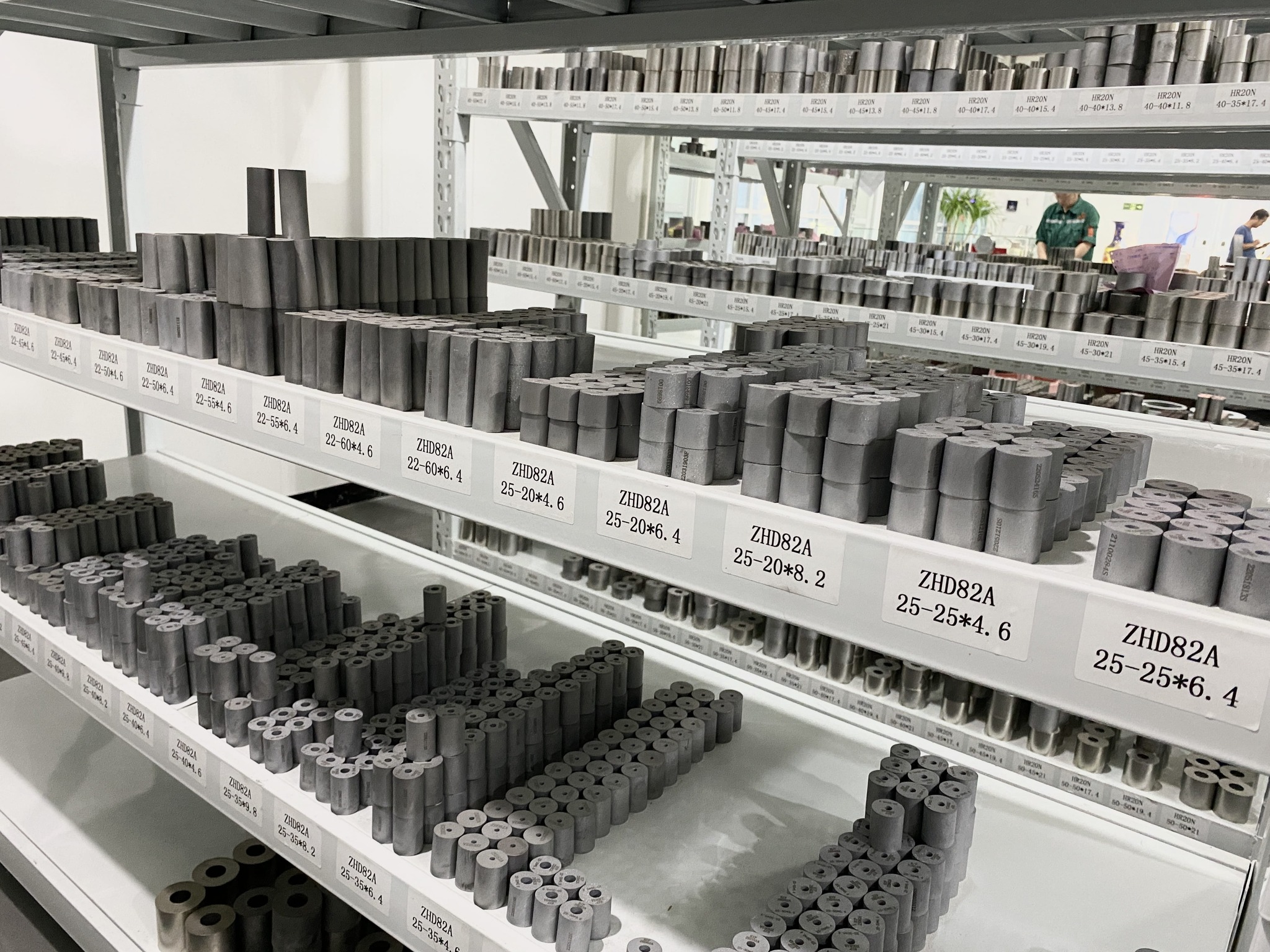

2. Osayizi abaningi nezinhlobo ezitholakalayo ze-OEM.

3. Yenziwe ngezinto zokwakha zekhwalithi ephezulu ezingu-100%.

4. Ithimba lokukhiqiza lochwepheshe, ukulethwa okusheshayo

5. Isevisi yamahhala ekhokhelwa emva kokuthengisa kanye nokusekelwa kwezobuchwepheshe

| ungsten Carbide Cold Forging/heading Dies | ||||

| Amabanga | Ukuminyana | TRS | Ukuqina | Ukusebenza nohlelo lokusebenza kuyanconywa |

| g/cm³ | I-MPa | HRA | ||

| YG11 | 14.4 | ≥3000 | 88.5 | Ukwakha noma ukugxiviza kufa ngenxa yezimpushana zensimbi nezimpushana ezingezona ezensimbi. |

| YG15 | 14 | ≥3400 | 87.5 | Ngokwenza umdwebo ufa ngamashubhu ensimbi nezinduku ngaphansi kwe-High compressibility ratio;ukubhoboza, ukunyathela, ukukha amathuluzi ngaphansi kwengcindezi enkulu. |

| YG20 | 13.5 | ≥3800 | 85.5 | Ukuze kwenziwe isitembu sezingxenye zewashi, amapuleti e-spring wezinsimbi zomculo, izimbiza zebhethri, amabhola ensimbi anosayizi omncane, izikulufu, ama-screw cap. |

| YG15C | 14 | ≥4000 | 86.5 | Ukuze uthole izingcezu zokubhoboza ama-cone kawoyela, sika amatshe athambile naqinile;ukudabula nokusika izinkuni eziqandisiwe, ukhuni oluthambile kanye nokhuni lokuqala. |

| YG16C | 13.9 | ≥3500 | 85.5 | Ukuqiniswa komthelela kuyafa. |

| YG18C | 13.7 | ≥3600 | 84.5 | I-Impact resistance forging ifa, i-hot-press forging iyafa namarola. |

| YG20C | 13.5 | ≥3800 | 83.5 | Ifa ngenxa yokusetshenziswa kokumelana nokugqokwa noma ukumelana nomthelela. |

| YG22C | 13.3 | ≥4000 | 83 | Ukwakhiwa kwamantongomane kuyafa futhi ukukhanga komthelela omkhulu wokumelana kuyafa. |

| YG25C | 13.1 | ≥4250 | 82.5 | Ikhanda lebhawodi elingenasici liyafa namarola. |

Ukufaniswa Kwempahla→Ukugaywa Kwebhola Elimanzi→I-WC exubile kanye Amandla e-Cobalt→Ukucindezela→Izifudumezi Zokuhlanganisa E-HIP→Ukutholwa kwe-QC→Ukupakisha

- Yonke inqubo yokukhiqiza inomuntu okhethekile okufanele amhlole ukuze aqinisekise ikhwalithi

- Yiba nonjiniyela abangochwepheshe ukuze bahlole ikhwalithi

- Yonke imikhiqizo ingaphansi kokuphathwa kwesistimu yekhwalithi eqinile esekelwe ku-ISO9001:2008

1. Impendulo phakathi kwamahora angu-48;

2. Ukuxhumana okuhle kwesiNgisi;

3. Isiphakamiso sochwepheshe ngomkhiqizo;

4. Ukuqeqeshwa okuhle komuntu othengisa izinto ezithunyelwa ngaphandle;

5. Unekhono lokudayisa i-tungsten carbide;

6. Ngemva kwenkonzo yokuthengisa.

Sizoletha impahla ekhiqizwe ngobuningi zingakapheli izinsuku ezingama-30 ngemuva kokukhokha kancane, kanti, uma kunezicelo ze-soecific ngesikhathi sokulethwa.Singenza ushintsho ngokwesicelo samakhasimende, ngakho-ke isikhathi esifushane sokulethwa sitholakala ngokuphelele.

Ngokuvamile 30% T/T kusengaphambili, bhalansi 70% ngokumelene B/L ikhophi.Futhi ingashintsha ngokwesicelo samakhasimende.

Senza izingxenye ezinomumo nosayizi abahlukene ukuze zifane nezidingo zamakhasimende ethu ncamashi, kungakhathaliseki ukuthi adinga amabhulokhi noma amashidi, amasilinda, amabheringi, amathiphu noma amazinyo.