I-15% Cobalt YG15 I-Tungsten Carbide Cold Heading Ifela Umshini Okhanda Obandayo

I-HengRui Cemented carbide ingumkhiqizi ochwepheshe we-carbide enosimende e-China.Le nkampani izibophezele ocwaningweni nasekuthuthukiseni, ekukhiqizeni nasekuthengisweni kwezinto ezintsha kanye nemikhiqizo emisha ye-carbide enosimende.Kuze kube manje sesenze uchungechunge oluningi lwemikhiqizo emikhulu ehlanganisa izinduku ze-carbide zikasimende, amapuleti, isikhunta, i-dis cutter, amathuluzi ezimayini nabanye abathungi abakhethekile.Ngaphezu kwalokho imikhiqizo yethu inikezwe isiqinisekiso se-ISO9001:2008.Akufanele ukhathazeke ngekhwalithi yomkhiqizo wethu.

| I-Tungsten Carbide Cold Forging/heading Iyafa | ||||

| Amabanga | Ukuminyana | TRS | Ukuqina | Ukusebenza nohlelo lokusebenza kuyanconywa |

| g/cm³ | I-MPa | HRA | ||

| YG11 | 14.4 | ≥3000 | 88.5 | Ukwakha noma ukugxiviza kufa ngenxa yezimpushana zensimbi nezimpushana ezingezona ezensimbi. |

| YG15 | 14 | ≥3400 | 87.5 | Ngokwenza umdwebo ufa ngamashubhu ensimbi nezinduku ngaphansi kwe-High compressibility ratio;ukubhoboza, ukunyathela, ukukha amathuluzi ngaphansi kwengcindezi enkulu. |

| YG20 | 13.5 | ≥3800 | 85.5 | Ukuze kwenziwe isitembu sezingxenye zewashi, amapuleti e-spring wezinsimbi zomculo, izimbiza zebhethri, amabhola ensimbi anosayizi omncane, izikulufu, ama-screw cap. |

| YG15C | 14 | ≥4000 | 86.5 | Ukuze uthole izingcezu zokubhoboza ama-cone kawoyela, sika amatshe athambile naqinile;ukudabula nokusika izinkuni eziqandisiwe, ukhuni oluthambile kanye nokhuni lokuqala. |

| YG16C | 13.9 | ≥3500 | 85.5 | Ukuqiniswa komthelela kuyafa. |

| YG18C | 13.7 | ≥3600 | 84.5 | I-Impact resistance forging ifa, i-hot-press forging iyafa namarola. |

| YG20C | 13.5 | ≥3800 | 83.5 | Ifa ngenxa yokusetshenziswa kokumelana nokugqokwa noma ukumelana nomthelela. |

| YG22C | 13.3 | ≥4000 | 83 | Ukwakhiwa kwamantongomane kuyafa futhi ukukhanga komthelela omkhulu wokumelana kuyafa. |

| YG25C | 13.1 | ≥4250 | 82.5 | Ikhanda lebhawodi elingenasici liyafa namarola. |

1. Amalebhu okuhlola amakhemikhali namakhemikhali ukuze alawule ikhwalithi

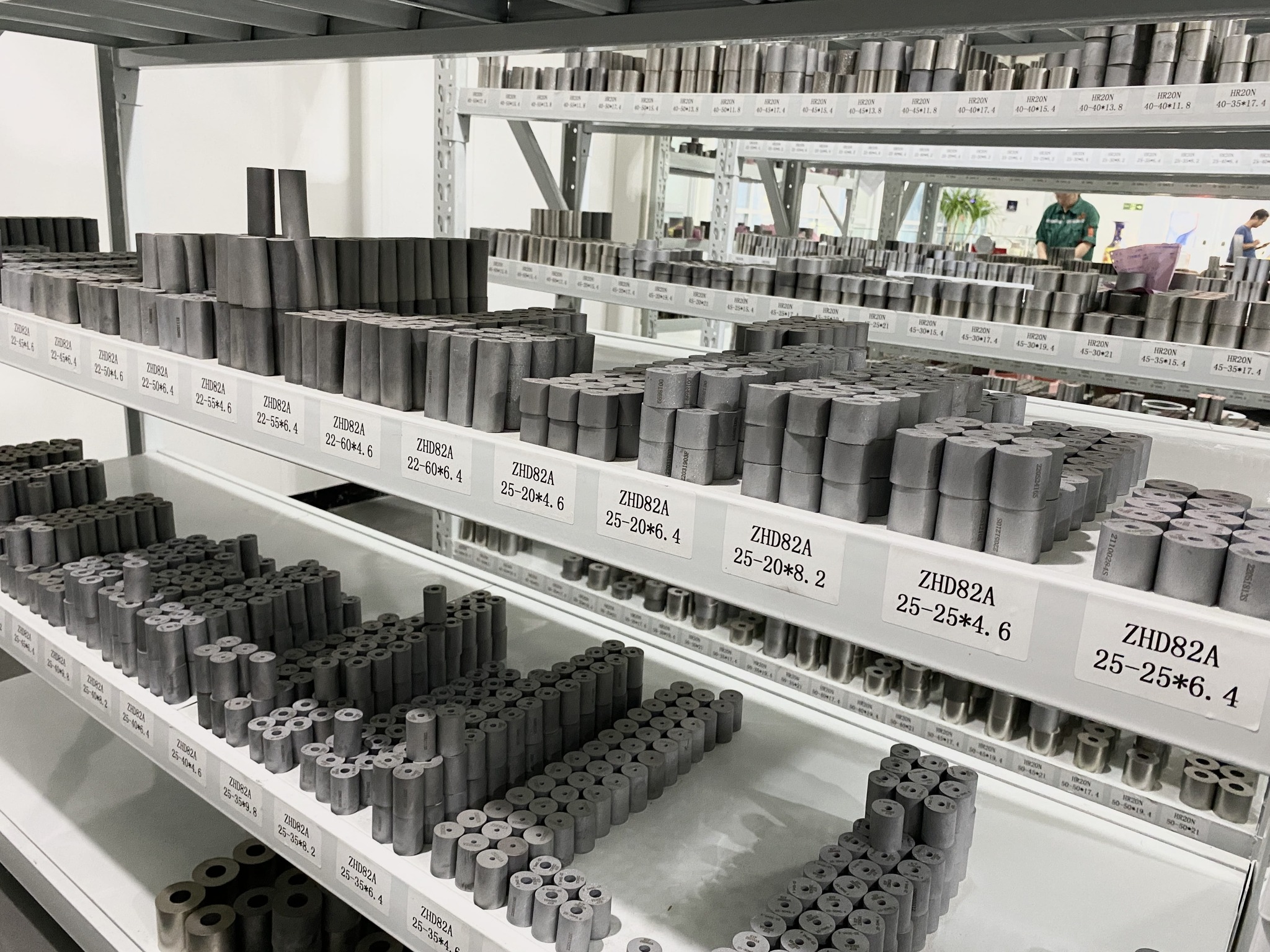

2. Uhla olugcwele lwezinhlobo ezitholakalayo, luhlangabezana nezidingo ezahlukene ze-customre.

3. Ikhwalithi ezinzile, isikhathi esifushane sokulethwa ngentengo yokuncintisana

4. Ukunemba okuphezulu ngempilo ende yesevisi

5. Iphakethe lochwepheshe, elivikela imikhiqizo emonakalweni

Ukufaniswa Kwempahla→Ukugaywa Kwebhola Elimanzi→I-WC exubile kanye Amandla e-Cobalt→Ukucindezela→Izifudumezi Zokuhlanganisa E-HIP→Ukutholwa kwe-QC→Ukupakisha

1. Sizozama konke okusemandleni ethu ukuphendula isicelo samakhasimende ethu phakathi namahora angama-24.

2. Sizogcina ukuxhumana okusebenzayo nokuphumelelayo namakhasimende ethu.

3. Sihlinzeka ngokulawulwa kwekhwalithi yezinga lokuqala kanye nezinsizakalo zangemuva kokuthengisa.

Sizoletha impahla ekhiqizwe ngobuningi zingakapheli izinsuku ezingama-30 ngemuva kokukhokha kancane, kanti, uma kunezicelo ze-soecific ngesikhathi sokulethwa.Singenza ushintsho ngokwesicelo samakhasimende, ngakho-ke isikhathi esifushane sokulethwa sitholakala ngokuphelele.

Ngokuvamile 30% T/T kusengaphambili, bhalansi 70% ngaphambi kokulethwa.Futhi ingashintsha ngokwesicelo samakhasimende.

Senza izingxenye ezinomumo nosayizi abahlukene ukuze zifane nezidingo zamakhasimende ethu ncamashi, kungakhathaliseki ukuthi adinga amabhulokhi noma amashidi, amasilinda, amabheringi, amathiphu noma amazinyo.