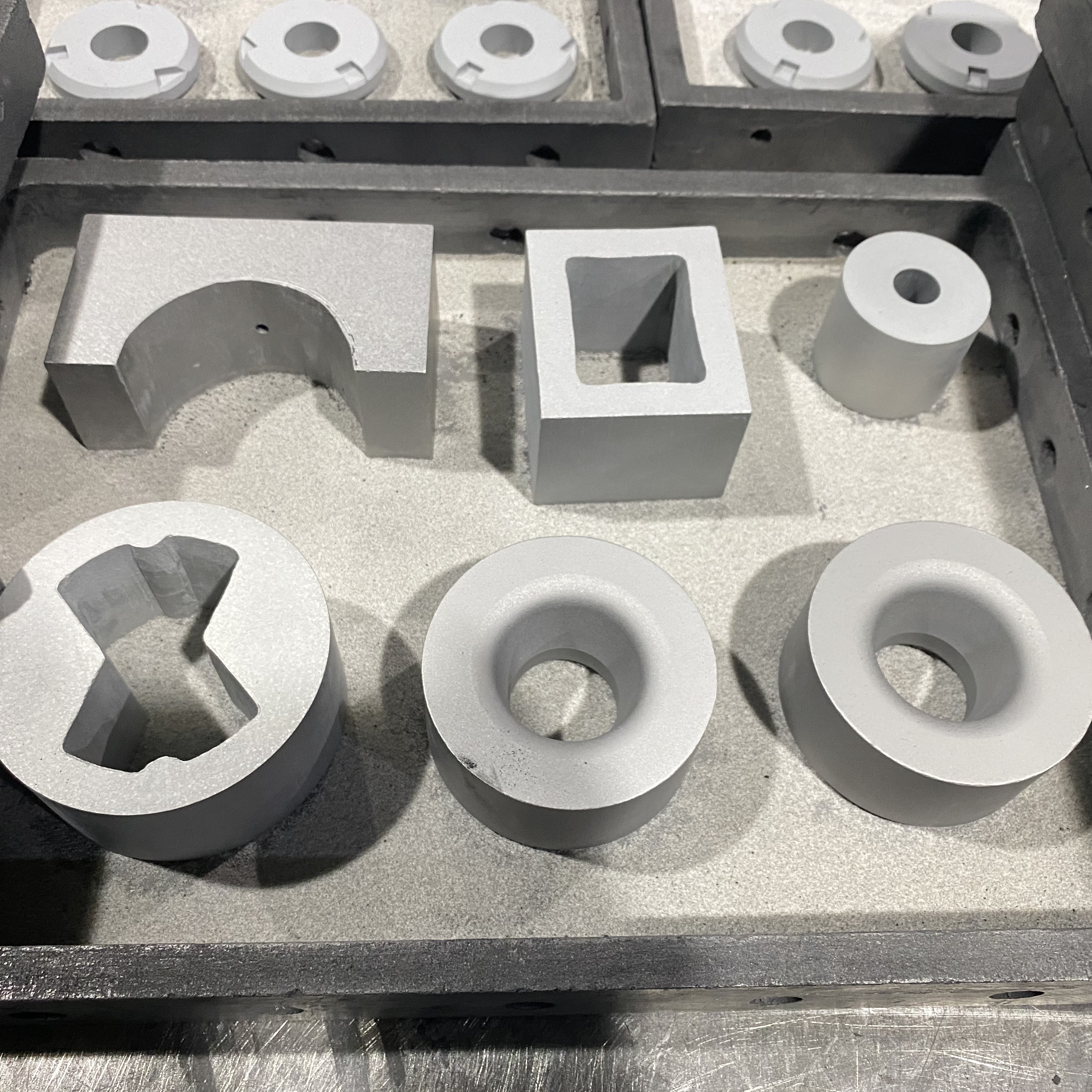

Ukucutshungulwa kwei-carbide enosimendei-liquid phase sintering, okungukuthi isigaba sokuhlanganisa kabusha sisesigabeni soketshezi.Amabhilidi acindezelwe ashiselwa ku-1350°C-1600°C esithandweni sevacuum.Ukuncipha komugqa kwe-billet ecindezelwe ngesikhathi sokucwiliswa cishe ku-18% futhi ukuncipha kwevolumu kuzungeze u-50%.Inani eliqondile le-shrinkage lincike kusayizi wezinhlayiyana ze-powder kanye nokwakheka kwe-alloy.

Sintering ofi-carbide enosimendekuyinqubo eyinkimbinkimbi ye-physicochemical, ehlanganisa ukususwa kwe-plasticizer, ukukhipha umoya, ukucwiliswa kwesigaba esiqinile, i-liquid phase sintering, i-alloying, ukuminyana, ukuchithwa kwemvula nezinye izinqubo.I-billet ecindezelweyo ifakwe ngaphansi kwezimo ezithile ukuze yakhe umkhiqizo onokwakheka kwamakhemikhali athile, isakhiwo, izakhiwo kanye nokuma nosayizi.Lezi zimo zenqubo ziyahlukahluka kakhulu kuye ngeyunithi ye-sintering.

I-carbide vacuum sintering eyi-cemented yinqubo lapho ukucwiliswa kwe-sinter kwenziwa ngaphansi kwe-1 atm (1 atm = 101325 Pa).I-Sintering ngaphansi kwezimo ze-vacuum kunciphisa kakhulu isithiyo sokuminyana yigesi ekhangisiwe endaweni eyimpushana kanye negesi esezimbotsheni ezivaliwe, esiza enqubweni yokusabalalisa nokuminyana, kugwema ukusabela phakathi kwensimbi nezinye izakhi ezisemkhathini ngesikhathi inqubo ye-sintering, futhi ingathuthukisa ngokuphawulekayo ukumanzisa kwesigaba se-liquid viscous kanye nesigaba esiqinile, kodwa i-vacuum sintering kufanele inake ukuvimbela ukulahlekelwa ukuhwamuka kwe-cobalt.I-vacuum sintering ingahlukaniswa ngezigaba ezine, okungukuthi isiteji sokususa i-plasticizer, isiteji sangaphambi kwe-sintering, isiteji sokushisa okuphezulu kanye nesiteji sokupholisa.

Isiteji sokususa i-plasticizer siqala emazingeni okushisa asekamelweni futhi sikhuphuke siye ku-200°C.Igesi ekhangiswa ebusweni bezinhlayiya zempushana ku-billet ihlukaniswa ebusweni bezinhlayiya ngaphansi kwesenzo sokushisa futhi ibalekela ku-billet ngokuqhubekayo.I-plasticizer ku-billet iyashisa futhi iphuma ku-billet.Ukugcina izinga eliphezulu le-vacuum kusiza ekuphumeni nasekubalekeni kwamagesi.Izinhlobo ezahlukene ze-plasticizers zinezakhiwo ezahlukene lapho zingaphansi kokushisa, ngakho-ke inqubo yokususa i-plasticizer kufanele ithuthukiswe ngokuvumelana nesimo esithile.

Inqubo yokukhipha ipulasitiki kufanele inqunywe ngokuya ngezimo ezithile zokuhlolwa.Izinga lokushisa elijwayelekile le-plasticizer gasification lingaphansi kuka-550 ℃.

Isiteji sangaphambi kwe-sintering sibhekisela ekushiseni okuphezulu kokushisa ngaphambi kwe-sintering, ukuze i-oksijini yekhemikhali ezinhlayiyeni zempushana kanye nokusabela kokunciphisa i-carbon ukukhiqiza igesi ye-carbon monoxide eshiya i-billet yokunyathelisa, uma le gesi ingakwazi ukukhishwa lapho kuvela isigaba se-liquid, izoba insalela ye-pore evaliwe ku-alloy, noma ngabe i-pressurized sintering, kunzima ukuyiqeda.Ngakolunye uhlangothi, ukuba khona kwe-oxidation kuzothinta kakhulu ukumanzisa kwesigaba se-liquid esigabeni esinzima futhi ekugcineni kuthinte inqubo yokuqina kwe-carbide enosimende.Ngaphambi kokuvela kwesigaba se-liquid, kufanele sikhishwe ngokwanele futhi kusetshenziswe i-vacuum ephakeme kakhulu.

Ukushisa kwe-sintering kanye nesikhathi se-sintering kuyimingcele yenqubo ebalulekile yokuhlanganiswa kwe-billet, ukwakheka kwesakhiwo esilinganayo kanye nokutholwa kwezakhiwo ezidingekayo.Izinga lokushisa le-sintering kanye nesikhathi se-sintering sincike ekubunjweni kwe-alloy, usayizi we-powder, amandla okugaya wengxube nezinye izici, futhi kulawulwa ukuklama okuphelele kwezinto.

Isikhathi sokuthumela: Jun-08-2023